COOLING TOWERS PROVIDE THE MOST EFFICIENT MEANS OF COOLING WATER

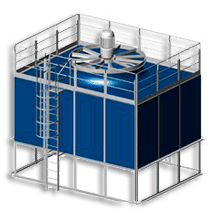

We are able to offer both forced draught and induced draught towers both as closed circuit and open circuit options with either axial or centrifugal fan sets. We are also able to offer evaporative condensers within our closed circuit range, a common solution within the food processing industry.

Please see below for our full range of GRP towers. If you are looking for stainless steel towers please contact us to speak to a technical sales engineer to discuss your specific requirements.

LATEST PRODUCT

Smart Cooling Towers

Protection and Control at your fingertips. Extend the lifespan of your equipment and its components, whilst monitoring its performance in real time.

View Range