INCREASED COOLING TOWER PERFORMANCE

Significant performance improvements and reductions in operating costs can be achieved by modifying cooling towers to reduce water temperatures. Following independent testing, the Vistech team will implement recommendations to deliver significantly improved cooling tower performance.

Replacing the packing and distribution system with high performance alternatives can reduce the cold water temperature by as much as 5°C.

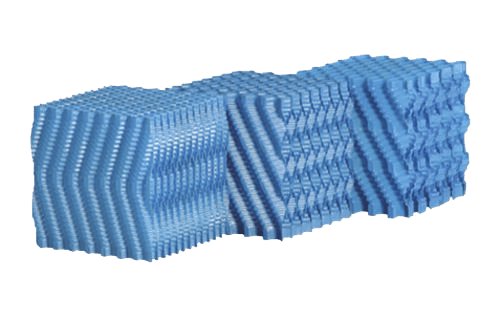

HIGH-PERFORMANCE & ANTI-LEGIONELLA PACKING

Cut operating costs and increase performance compared to original manufacturer’s packs. The polypropylene construction is environmentally friendly and the unique welded construction is more robust compared to glued or mechanically assembled packs.

The need for regular cleaning is well established in combating legionella. However, the surface area of packing is over 100 times that of the cooling tower casing and very much harder to clean. Water treatment may not reach all areas of the cooling tower. Sections of packing are may not be fully wetted and therefore can remain untreated.

Installation of anti-legionella packing solves the problem and can assist with the problem of system reinfection. The packing is impregnated with a wash/ leach resistant biocide that’s effective against a range of bacteria for up to 5 years.

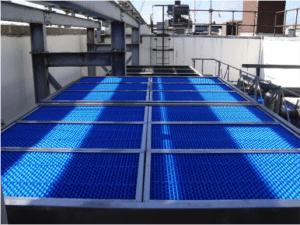

HIGH-PERFORMANCE DRIFT ELIMINATORS

We are able to provide high efficiency drift eliminators to suit any make or model of cooling tower, with framed and unframed options in both standard and anti-legionella material.

All Vistech Drift Eliminators:

- Provide high efficiency elimination in compliance with ACOP L8

- Tough plastic welded eliminator matrix

- Anti-legionella option provided

- Stainless steel framed option to protect the modules against damage when removed from the tower for cleaning and maintenance extending its useful life.