Plume abatement is often specified for cooling towers on the basis of visual impact or perceived environmental benefit. In reality, this practice almost always increases energy consumption, capital cost and system complexity for (unfortunately for many…) no good reason. For projects with genuine decarbonisation or energy-reduction objectives, plume abatement should be treated as an exception, not a default. This article sets out the real reasons plume abatement is specified, the technical and energy penalties it introduces, and the limited scenarios where it is genuinely justified.

What Cooling Tower Plume Actually Is

Visible plume from an evaporative cooling tower is not smoke, pollution or drift – a common misconception. It is simply warm, moisture-laden air leaving the tower and condensing when it meets the cooler ambient air. The water vapour was already present in the atmosphere – evaporation has just made it visible.

From an environmental standpoint, the plume of an evaporative cooling system has no direct carbon impact and no harmful emissions – Great! The only real effects are visual, and in some edge cases, localised fogging or icing.

Why Plume Abatement Gets Specified

In practice, plume abatement requirements usually come from one of four places:

Risk Aversion in Specifications

Some EPC or client specifications include plume abatement as a blanket requirement, often copied forward from previous projects without site-specific justification.

Planning or Visual Impact Constraints

Urban sites, neighbouring residential areas, or locations near roads, rail or airports may face planning conditions restricting visible vapour plumes – particularly in winter.

Supplier Differentiation

Plume abatement is sometimes used by equipment suppliers as a differentiator, rather than as a response to a defined operational or regulatory need.

Misplaced Sustainability Narratives

There is a persistent misconception that a visible plume equals inefficiency or environmental harm. In fact, suppressing plume typically increases energy use and indirect emissions.

How Plume Abatement Systems Work

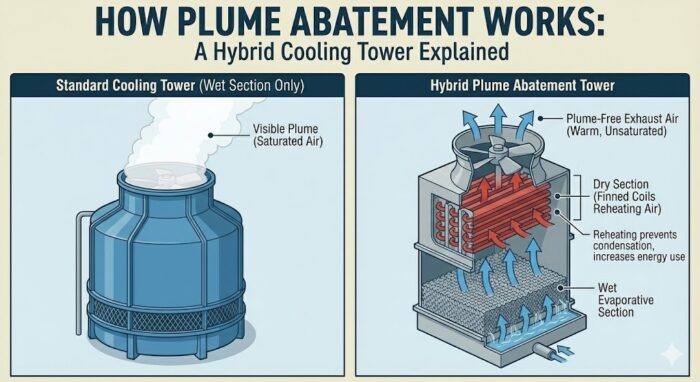

Plume abatement cooling towers are typically hybrid designs. They combine:

- A conventional wet evaporative section, and

- A dry or sensible cooling section (often finned coils)

The dry section reheats the saturated exhaust air, reducing its relative humidity so that condensation – and therefore visible plume – does not occur.

This reheating process is where the inefficiency is introduced.

The Energy and Carbon Penalty

Plume abatement does not come for free.

Increased Fan Power

Hybrid towers require higher air volumes and additional pressure drop across dry coils. This increases fan motor size and annual electricity consumption.

Larger Heat Exchange Surface

To deliver the same thermal duty, plume-abated towers are physically larger, with more steel, more fans and more parasitic energy losses.

Reduced Evaporative Effectiveness

Reheating exhaust air actively works against the thermodynamic advantage of evaporative cooling – the most energy-efficient method of heat rejection available.

Carbon Projects: The Contradiction

For carbon capture, decarbonisation or energy-reduction projects, this creates a fundamental contradiction: visible plume is removed, but electrical demand – and upstream emissions – increase.

Capital and Operational Trade-offs

Higher CAPEX

Plume-abated towers typically cost materially more than conventional induced-draft counterflow towers for the same duty.

Maintenance Complexity

Additional coils introduce fouling, cleaning and inspection requirements. Access, hygiene and long-term reliability must be engineered carefully.

Part-Load Performance

Plume abatement is most challenging in cold, part-load conditions – precisely when wet cooling towers are otherwise at their most efficient.

When Plume Abatement Is Justified

There are legitimate use cases:

- Planning conditions explicitly restrict visible plume

- Proximity to highways, rail lines or runways where fogging or icing is a proven risk

- Dense urban sites where visual impact is commercially unacceptable

In these cases, plume abatement may be unavoidable – but it should still be engineered with eyes open to the energy penalty.

When It Isn’t and Why That Matters

If plume abatement is not mandated by planning, safety or operational constraints, specifying it on sustainability grounds is usually counter-productive.

For projects claiming carbon reduction or energy optimisation – including carbon capture schemes – the most efficient solution is typically a conventional induced-draft wet cooling tower, correctly sized and controlled.

Suppressing plume to solve an aesthetic issue while increasing electrical demand is not decarbonisation. It is optics (did someone say green washing…)

Plume Abatement & Hybrid Cooling – FAQ

A stakeholder-ready checklist for planning, safety, energy, carbon, and operational performance. Use the search to quickly locate questions; expand answers for what evidence is typically expected.

Planning & Permitting

Is plume abatement mandated by planning or permit conditions?

Confirm whether plume abatement is a requirement (condition of consent/permit) or a design choice (visual/amenity mitigation).

- Review planning decision notice / environmental permit conditions and any discharge consents.

- Identify the exact condition wording and measurable acceptance criteria (e.g., “no visible plume beyond boundary”).

- Record the approving authority, reference number, and compliance evidence required.

Safety & Nuisance

Is there a quantified risk of fogging or icing?

This is typically addressed through a site-specific dispersion and microclimate assessment covering visible plume, drift deposition, and low-temperature conditions that could lead to surface icing.

- Use appropriate modelling (e.g., Gaussian/CFD as justified) with local meteorology and geometry.

- Assess receptors: roads, footpaths, loading bays, plant access routes, nearby buildings/air intakes.

- Quantify likelihood and severity (frequency, duration, affected area) and propose mitigations.

Energy & Performance

Has the energy penalty been modelled?

Hybrid/plume abatement solutions can introduce additional fan power, pumping, controls, or reheat/coil loads. Evidence normally includes annual energy modelling and design-point verification.

- Define baseline (conventional wet tower) and compare like-for-like duty, approach, and water temperatures.

- Model seasonal operation, part-load control, and winter modes (including plume abatement enable/disable logic).

- Report annual kWh, peak kW, and sensitivity to ambient temperature/humidity and load profile.

Carbon & Sustainability

Has whole-life carbon been assessed, not just visuals?

A robust position is a whole-life carbon (WLC) assessment: embodied carbon of additional materials plus operational emissions from energy/water/chemicals over the expected life.

- Embodied: casing/coils/extra fans, structural steel, additional plantroom footprint (if any).

- Operational: electricity, water make-up, water treatment, plume-abatement modes.

- Declare assumptions: lifetime, grid factors, maintenance/replacement schedules.

Operating Envelope

Are part-load and winter conditions considered?

Decision-makers usually expect confirmation that the proposed solution remains stable and safe across the full range: minimum load, winter ambient, and transient conditions.

- Document minimum controllable fan speed, turndown, basin/pipework freeze protection, and start/stop logic.

- Show winter plume behaviour (including defrost or dry-coil operation if applicable).

- Confirm water treatment and Legionella control strategy across reduced load/temperature conditions.

Options Appraisal

Has a conventional wet tower been evaluated as a baseline?

A clear baseline improves credibility: it demonstrates whether plume abatement is proportionate versus simpler measures (layout, discharge height, screening, operational constraints).

- Define baseline configuration and performance (approach, range, fan power, water use, noise).

- Compare CAPEX/OPEX, risk (fog/icing), and compliance position.

- Provide a decision matrix with weighted criteria (planning risk, energy, carbon, cost, programme).

Basis of Design

Are hybrid alternatives being driven by spec or evidence?

Clarify the “why” behind the selection: mandated requirement, client preference, planning risk mitigation, or quantified operational benefits. Ideally this is captured in a Basis of Design (BoD).

- State the driver(s): planning condition, stakeholder concern, site constraints, or quantified risk.

- Link the choice to modelling outputs and an options appraisal (not just vendor literature).

- Document any rejected alternatives and why (space, noise, performance, cost, programme).

Operations

Is additional maintenance budgeted and resourced?

Hybrids/plume abatement can add coils, dampers, controls, sensors, and cleaning regimes. Evidence usually includes a maintenance plan, spares strategy, and OPEX allowance.

- Identify additional tasks: coil cleaning, fin protection, drift eliminator checks, actuator calibration.

- Confirm access, isolation, and safe maintenance (working at height, water hygiene procedures).

- Budget: labour hours, consumables, downtime allowance, and critical spares holding.

Acoustics & Electrical

Are fan power and noise impacts understood?

Plume abatement arrangements can increase fan count, static pressure, and operating hours. Decision-makers typically want fan power calculations plus an acoustic assessment at sensitive receptors.

- Electrical: peak kW, diversity, motor starting, VSD strategy, and standby arrangements.

- Acoustics: octave-band data, tonality, nighttime criteria, and mitigation (attenuators, barriers, speed limits).

- Confirm that control strategy won’t inadvertently push operation into non-compliant noise modes at night/winter.

Site Validation

Has a site-specific survey been completed?

Site constraints drive both plume behaviour and practicality. A site-specific survey typically covers geometry, elevations, nearby obstacles, access routes, and receptor mapping.

- Confirm available footprint, discharge height constraints, and proximity to boundaries/roads/walkways.

- Capture obstructions and recirculation risks (parapets, adjacent buildings, screens).

- Use local wind data and validate proposed locations against safety/amenity considerations.