For many UK manufacturers, upgrading or replacing a cooling system can be a headache from the outset…. turnkey solution? Tendering? FEED requirements? Which/What/Who/How? So many questions with little guidance. Obtaining supplier quotations in isolation often leads to over-specification, unbudgeted extras, or systems that simply don’t perform as expected. Vistech has experienced this too many times before, and the client journey is so important. Discovery, Design, Delivery – this replaces guesswork with data, enabling you, the client to to make the correct informed decision. Through structured Health Checks, Performance Surveys, and detailed design, we’ve been able to guide clients from uncertainty to clarity, reducing waste, risk, and total lifecycle cost.

Why Cooling System Clarity Matters

Cooling systems are often inherited, expanded, and patched over decades. Few sites can confidently state their real heat load, water use, or efficiency. That’s why “just quote for a new tower” is one of the costliest sentences we hear in our industry. Before equipment selection comes understand of your processes customary requirements. The Discovery–Design–Delivery journey is how Vistech brings that understanding into focus.

Discovery – The Cooling System Health Check Process

A Cooling System Health Check is Vistech’s entry point to any upgraded cooling system. It’s the best starting point, as a structured diagnosis of your system carried out by a senior consultant engineer, combining a one-day site visit, visual inspection, on-site engineering employee interviews, and analysis.

The process typically includes:

- Walkthrough assessment: inspection of towers, pumps, pipework, and controls.

- Discussions with operators: understanding duty cycles, downtime causes, system pain points and water treatment routines.

- Operational benchmarking: comparing performance against expected loads and current system configuration.

- Report and recommendations: a concise two-page summary highlighting inefficiencies, risks, and upgrade priorities.

- Budgetary guidance: high-level CAPEX estimates for potential improvements, helping clients plan investment sensibly.

The deliverable to the client is clarity. A Health Check defines where the site stands today and whether the system is fundamentally sound or a candidate for replacement.

Design – The Cooling System Performance Survey Process

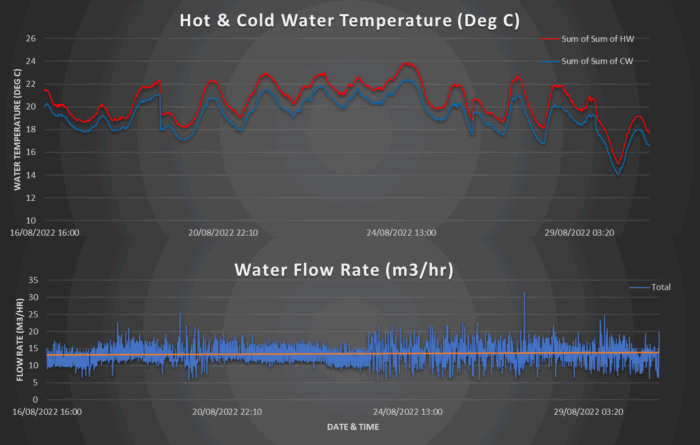

When the Health Check identifies the potential efficiency gains, the next step is the Performance Survey. This is a non-intrusive monitoring study that quantifies the actual thermal performance of the current cooling system during a live production period.

The process involves:

- Non-intrusive sensor installation – measuring temperature, flow, and power usage on the live system/s without interrupting production.

- Data collection period – typically two weeks, covering high-load and normal operation cycles for the primary process.

- Secure data transmission – via an independent 4G gateway, separate from client IT networks.

- Analysis and reporting – Vistech’s engineering team process the data off-site to establish real load profiles, peak and average duties, and energy/water consumption.

- System optimisation advice – recommendations from a baseline performance analysis resulting in correct equipment selection.

Case example: A plastics manufacturer believed they needed an 800 kW replacement cooler. The Performance Survey proved the true peak demand was 520 kW. That evidence reduced their capital outlay by £100,000, cut electrical demand by a third, and enabled a right-sized system that ran more efficiently.

Typical cost: around £5,000–£10,000, depending on the complexity of monitoring points and number of individual systems – importantly… zero downtime required.

The Performance Survey builds possibly the most important part of the evidence base for the next phase of detailed design and budget definition, ensuring the final system is grounded in live data collection and analysis.

Delivery – From Validated Design to Implementation

With validated load data and a prioritised roadmap of efficiency gains for the client’s project, Vistech moves into detailed engineering and delivery. This next phase is evidence-led, ensuring full confidence in the solution.

At a pharmaceutical site, Performance Survey data formed the backbone of their CAPEX justification pack. The board approved the upgrade within weeks, not months, because every efficiency claim was grounded in data and not ‘hearsay’ or on the word of an ‘expert’.

Delivery is where design intent becomes performance reality safely, compliantly, and without mid-project redesign.

Real-World Results

Across UK manufacturing sites, the Health Check + Performance Survey sequence typically yields:

- 10–25%+ energy and water savings.

- 30–50%+ faster CAPEX approval through validated ROI data.

- Reduced downtime and maintenance costs by identifying inefficiencies early.

- Improved compliance with HSG274, ACOP L8, and environmental planning.

Practical Checklist: 10 Steps for Project Managers

- Capture post-project data for future optimisation.

- Gather existing P&IDs, site layouts, and maintenance logs.

- Begin with a Health Check to establish a baseline condition.

- Use survey data to validate design duties.

- Quantify load using non-intrusive sensors — don’t rely on legacy data.

- Engage maintenance teams early – they know the hidden issues.

- Align project outcomes to energy, water, or carbon objectives.

- Use validated data to drive outline budgets.

- Verify compliance early (noise, planning, HSG274 / ACOP L8).

Include lifecycle cost analysis in every funding submission.

Cooling System Upgrade FAQs

The questions below come up on almost every UK project we support – from “Do we actually need a new tower?” to “How disruptive is a Performance Survey?”. Use this as a quick reference for the full Discovery–Design–Delivery journey.

The Health Check is the entry point – a structured condition and risk review carried out by a senior consultant. It tells you if the existing system is fundamentally sound, underperforming, or a liability.

The Performance Survey then quantifies actual thermal load and run profile using temporary sensors. This prevents over-sizing and reveals how much capacity you really use.

- Small, simple systems may proceed after a Health Check alone.

- For multi-line plants, critical processes, or unclear load history, both stages are strongly recommended.

In practice, the combination typically pays for itself through avoided over-specification and fewer “design changes” during delivery.

A Health Check is non-intrusive. We work with your engineering and operations teams to plan access around production:

- Towers, pumps, and pipe routes are inspected during normal running.

- Operator interviews are scheduled in short blocks to avoid disrupting shifts.

- Any physical checks that do require isolation are planned into existing shutdowns.

You retain full control of permits and isolations; the outcome is a clear condition snapshot without interrupting throughput.

Performance Surveys are designed for zero downtime. We:

- Install temporary flow, temperature, and power sensors on key circuits.

- Use an independent 4G gateway, avoiding your IT network.

- Collect data over high-load and normal operation, often 10–14 days.

You keep running as normal; the only change is that, for once, you know exactly what the system is doing rather than assuming it from nameplate data.

Many plants specify replacement coolers at the original design duty, or at a figure rounded up “just to be safe”. That is often tens of percent higher than reality.

The Performance Survey:

- Maps real peak and average loads, not assumed nameplate values.

- Highlights diversity across lines – where simultaneous peak load is unlikely.

- Provides time-of-day and seasonal insight used directly in FEED and sizing.

In practice this can trim hundreds of kilowatts of “ghost load” from the design – and with it, fan power, pump power, and installed CAPEX.

Front-End Engineering Design (FEED) uses the validated data to lock in:

- Confirmed design duties and turndown ranges.

- Preferred technologies (tower, adiabatic, hybrid, chiller).

- Hydraulic, electrical, and control philosophies.

- Key constraints – noise, footprint, structural limits, water availability, L8/HSG274 controls.

Suppliers then price the same scope and the same performance guarantees, rather than competing on different interpretations of a vague brief.

Finance teams usually respond well to a simple comparison:

- Survey cost vs. capital saved by right-sizing (often tens of thousands of pounds).

- Energy and water savings from a system that matches the real load profile.

- Faster CAPEX sign-off thanks to bankable data and a defensible ROI model.

In many projects, a single avoided “oversize” cooler or chiller more than covers the survey investment.

With Discovery–Design–Delivery, the tender pack already includes:

- Measured duty and diversity data.

- Preferred system architecture and control strategy.

- Clear constraints on footprint, noise, connections, and shutdown windows.

- Defined deliverables – drawings, commissioning tests, training, documentation.

Suppliers then compete on quality, value, and execution rather than who has made the boldest assumption about your process.

During Discovery and FEED we capture:

- Existing control measures, risk assessments, and logbooks.

- Access requirements for inspection, sampling, and cleaning.

- Preferred drift-control technologies and water-treatment approach.

The resulting specification can then call out compliance-critical items as mandatory, rather than leaving them to installer “interpretation”.

Ideally, have the following available:

- Latest P&IDs and general arrangement drawings.

- Recent energy and water bills or metered data for the cooling plant.

- Maintenance history, major faults, and any open actions from risk assessments.

- Known bottlenecks or “problem lines” reported by production or operators.

None of this is mandatory, but it allows us to move faster and provide a sharper set of recommendations.

The usual pattern is:

- Agree a Health Check scope and target system (or systems).

- Use findings to decide whether a Performance Survey is warranted.

- Build FEED and funding documents from real data, not assumptions.

From there, we can either support you through tendering or act as your turnkey partner for design, installation, and early-life optimisation.