For UK Manufacturing companies operating cooling towers, evaporative condensers etc. the quality of engineered metalwork is fundamental to safety, efficiency, and long-term reliability. Vistech has become one of the UK’s leading providers of bespoke stainless-steel metalwork solutions, supporting asset owners, FM teams, and industrial clients with precision-manufactured components built to perform in the most demanding evaporative environments.

Backed by decades of engineering experience, Vistech can design and manufacture fully customised metalwork assemblies that not only ensure you continue to meet original duty requirements of your process cooling system but significantly extend service life of the key components within your system particularly in corrosive, coastal, or high-load applications.

Why Stainless Steel? Long-Term Protection in a Harsh Environment

Cooling towers and adiabatic systems operate in high-humidity, high-airflow, variable-temperature environments where corrosion rapidly affects mild steel. In our experience on of the first things to show these signs are fan casings and guard rings which when exposed to high-moisture environments degrade quickly, compromising efficiency and posing a large hygiene risk.

The solution is refurbishment of these units using custom-engineered stainless steel parts, which offers:

- Exceptional corrosion resistance

- Structural rigidity and long design life

- Lower maintenance requirements

- Compliance with Legionella-control best practice

- Reduced downtime and lifecycle cost

Vistech has done for years and continues to produce metalwork in both 304 and 316 stainless steel, selecting the right grade depending on environmental conditions e.g., standard duty applications, coastal installations, or chemically aggressive atmospheres.

Complete Bespoke Fabrication Capability

Vistech manufactures a wide range of stainless-steel components, including:

1. Fan Casings & Impeller Assemblies

Custom-built split stainless-steel fan casings, DIDW impellers, inlet cones, bearing support rings, precision-ground shafts and stainless-steel drive guards.

These assemblies are engineered to fit seamlessly into the existing plant footprint removing the need for structural alterations or costly cranage.

2. Structural Stainless-Steel Components

- Access doors and sump doors

- Internal supports, pack rails and structural bracing

- Tanks

- Stainless-steel brackets, nozzles and pipework connections

These components are manufactured to precise tolerances, providing long-term stability and extending the life span of the tower and it’s structure.

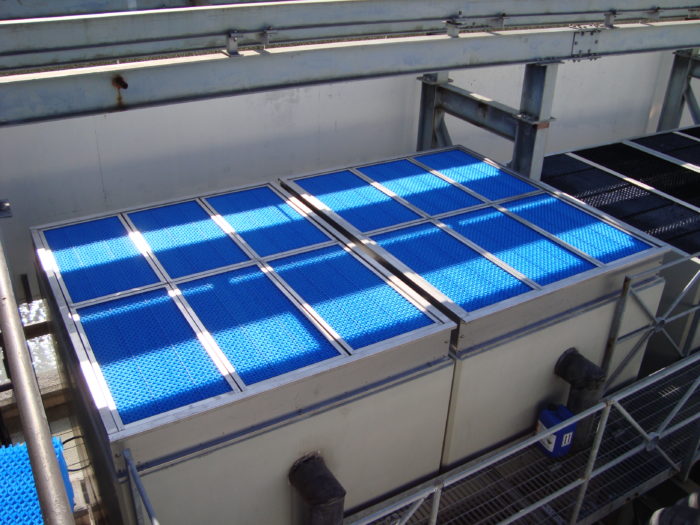

3. Stainless-Steel Drift Eliminator & Inlet Louvre Frames

Strong welded frames give complete edge protection and ensure perfect seals between eliminator media and the casing walls helping prevent drift bypass and improving overall tower efficiency.

4. Custom Fabrication for Unique Site Constraints

From tight rooftop restrictions to bespoke fan casings, Vistech’s metalwork is designed to be installed efficiently, often eliminating the need for crane lifts.

Split casings, demountable rings and modular sections allow for safe manual handling on congested roofs or within plant rooms – something that isn’t always an initial consideration but can become an incredibly large headache…..

From Design to Manufacture: A Fully Engineered Service

Vistech’s stainless-steel solutions are designed in-house using specialist fabricators, providing complete control over specification, quality and delivery. Each project follows a structured methodology:

Engineering Survey & Dimensional Capture

Technicians undertake a detailed site survey to capture existing mechanical requirements, interfaces and dimensions.

CAD Design and Bespoke Fabrication

Using precise measurements, Vistech creates custom drawings and manufactures components built to meet or exceed the original duty of the towers onsite.

Quality Assurance

All stainless-steel fabrications undergo inspection for dimensional accuracy, weld integrity, finish quality and correct fitting. Further to this we can complete static and dynamic balancing on the fan’s we complete and supply to you along with a whole other host of testing capability.

Ease of Installation

All assemblies are designed for rapid installation, minimal disruption, and maximum system uptime.

Applications Across Cooling and Process Systems

Vistech’s bespoke metalwork solutions support:

- Cooling towers (open and closed circuit)

- Evaporative condensers

- Adiabatic coolers

- Access platforms and maintenance infrastructure

Our capabilities are across everything from full tower refurbishment to precision-engineered supply-only kits for OEM-compatible replacements.

Advantages of Choosing Vistech Bespoke Metalwork

- Extended service life over standard coated or galvanised steel

- Improved hygiene and reduced Legionella risk

- Better energy efficiency due to optimised airflow and reduced turbulence

- Perfect fit, regardless of the age or brand of existing plant

- Customisation for duty upgrades, efficiency projects or replacement programmes

- Lower total cost of ownership

- Fast turnaround with high accuracy and consistent quality

A Manufacturing Partner for Long-Term Asset Reliability

Whether clients require a single replacement component or a complete stainless-steel fan assembly, Vistech delivers engineered solutions built for longevity, safety, and performance.

Recent projects consistently have demonstrated Vistech’s design, the quality of fabrication, and the ability to solve complex on-site issues with custom-built stainless-steel engineering.