What Is A Cooling Tower?

Cooling towers are highly efficient means of cooling water transferring the heat from the water to atmosphere and are used for both manufacturing process cooling plus HVAC applications on large buildings that have air conditioning.

How Does A Cooling Tower Work?

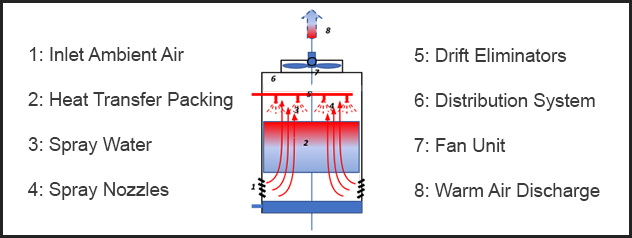

Cooling towers use the process of evaporation to cool water. The water requiring cooling is pumped to the cooling tower and distributed by spray nozzles in a thin film over the heat transfer surface (Fill or Packing) within the cooling tower.

As the water passes through the packing it is brought into contact with air drawn or forced through the tower by the cooling tower fans. This causes a small proportion of the water to be evaporated, approximately 3%

What Happens Next?

The process of evaporation causes an energy transfer from the hot cooling water to the evaporated water in the form of latent heat transfer. The remaining water is cooled, which is collected in the cooling tower sump and pumped to the process or equipment requiring the cooled water.

Approximately 20 % of the heat is also removed from the water by sensible cooling the remaining heat transfer is largely by evaporation.

What Types Of Mechanical Draft Cooling Towers Are There?

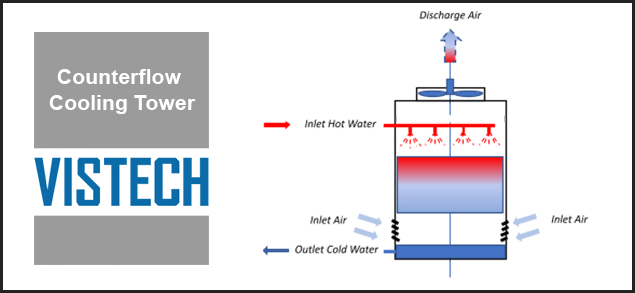

Counterflow Cooling Towers

In a counterflow cooling tower the air travels vertically upwards through the cooling tower packing whilst the water travels vertically down in “counterflow” to the air. Counterflow towers can either be induced draught as shown in the diagram below with the fan drawing air through the cooling tower or forced draft with the fan mounted on the side of the unit below the packing forcing air through the packing.

Forced draught towers have a high inlet air velocity and low discharge air velocity and tend to be more prone to recirculation of the discharge vapour which will cause a reduction in the tower performance.

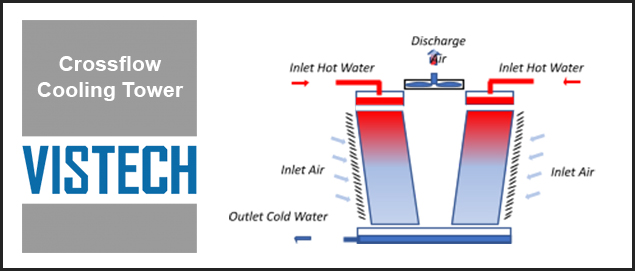

Crossflow Cooling towers

In a crossflow cooling tower the path of air through the packing is horizontal whilst the water falls by gravity vertically downwards through the packing. As with counterflow cooling towers cross flow towers may be of either induced draught design with the fan sited at the air discharge or forced draught design with the fan mounted on the side of the unit.

Cross flow towers have larger air openings in the side of the unit than counterflow towers which may increase the potential for aerosol escape and sunlight penetration.

What Is Legionnaires Disease?

Legionellosis is a collective term for diseases caused by legionella bacteria including the most serious Legionnaires’ disease, as well as the similar but less serious conditions of Pontiac fever and Lochgoilhead fever. Legionnaires’ disease is a potentially fatal form of pneumonia and everyone is susceptible to infection. The risk increases with age but some people are at higher risk including:

- people over 45 years of age

- smokers and heavy drinkers

- people suffering from chronic respiratory or kidney disease

- diabetes, lung and heart disease

- anyone with an impaired immune system

The bacterium Legionella pneumophila and related bacteria are common in natural water sources such as rivers, lakes and reservoirs, but usually in low numbers. They may also be found in purpose-built water systems such as cooling towers, evaporative condensers, hot and cold water systems and spa pools.

If conditions are favourable, the bacteria may grow increasing the risks of Legionnaires’ disease and it is therefore important to control the risks by introducing appropriate measures outlined in Legionnaires’ disease – The Control of Legionella bacteria in water systems (L8).

Where does it come from?

Legionella bacteria are widespread in natural water systems, e.g. rivers and ponds. However, the conditions are rarely right for people to catch the disease from these sources. Outbreaks of the illness occur from exposure to legionella growing in purpose-built systems where water is maintained at a temperature high enough to encourage growth, e.g. cooling towers, evaporative condensers, hot and cold water systems and spa pools used in all sorts of premises (work and domestic).

How do people get it?

People contract Legionnaires’ disease by inhaling small droplets of water (aerosols), suspended in the air, containing the bacteria. Certain conditions increase the risk from legionella if:

- the water temperature in all or some parts of the system may be between 20-45 °C, which is suitable for growth.

- it is possible for breathable water droplets to be created and dispersed eg aerosol created by a cooling tower, or water outlets

- water is stored and/or re-circulated.

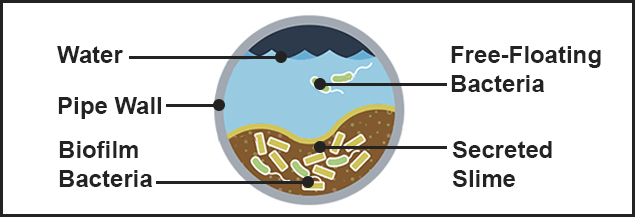

- there are deposits that can support bacterial growth providing a source of nutrients for the organism e.g. rust, sludge, scale, organic matter and biofilms

Cooling Tower Glossary

There are a lot of terms to know when dealing with Cooling Towers, some are self-explanatory while others need a little more explanation. Below is a comprehensive glossary of the terms used when referring to Cooling Towers.

- Air inlet: Opening in a cooling tower through which air enters. Sometimes referred to as the louvered face on induced-draft towers.

- Air Rate: Mass flow of dry air per square metre of cross-sectional area in the tower’s heat transfer region per hour.

- Air Travel: Distance which air travels in its passage through the fill. Measured vertically on counterflow towers and horizontally on crossflow towers.

- Air Velocity: Velocity of air-vapor mixture through a specific region of the tower (i.e. the fan.)

- Ambient Wet Bulb Temperature (AWB): The wet bulb temperature of the air encompassing cooling tower not including any temperature contribution by the tower itself.

- Approach: The temperature difference between the cold-water temperature and the ambient or entering wet bulb temperature (LWT-WBT= Approach)

- Blowdown or bleed: Water discharged from the system to control concentrations of salts or other impurities in the circulating water.

- Capacity: The amount of water (l/s) that a cooling tower will cool through a specified range, at a specified approach and wet bulb temperature.

- Cell: Smallest tower subdivision which can function as an independent unit with regard to air and water flow; it is bounded by either exterior walls or partition walls. Each cell may have one or more fans and one or more distribution systems.

- Cold Water Temperature (CWT): Temperature of the water leaving the collection basin or sump, exclusive of any temperature effects incurred by addition to make up and/or the removal of blowdown. Unit: ℃

- Counterflow: Air flow direction through the fill or packing is counter current to that of the falling water.

- Crossflow: Air flow direction through the fill or packing is essentially perpendicular to that of the falling water

- Delta T: Difference between the hot water temperature and the cold-water temperature (HWT-CWT= Range)

- Distribution Basin: Shallow pan-type elevated basin used to distribute hot water over the tower fill by means of orifices in the basin floor. Application is normally limited to crossflow towers.

- Distribution System: Those parts of a tower beginning with the inlet connection which distribute the hot circulating water within the tower to the points where it contacts the air for effective cooling. May include headers, lateral branch arms, nozzles, distribution basins, and flow-regulating devices.

- Drift: Circulating water lost from the tower as liquid droplets entrained in the exhaust air stream.

- Drift Eliminators: Inertial water droplet stripping devices used to reduce the amount of circulating water that can be entrained in the unit airflow and leave the equipment. Evaporative cooling equipment.

- Dry-Bulb Temperature: The temperature of the entering or ambient air adjacent to the cooling tower as measured with a dry-bulb thermometer.

- Evaporation Loss: Water evaporated from the circulating water into the discharge air stream as part of the in the cooling process in a cooling tower. Units are usually quoted in l/s or Kg/s

- Fan Deck: Surface enclosing the middle structure of an induced draft cooling tower, exclusive of the distribution basins on a crossflow tower.

- Fan Blade Angle: The angle which the blades of a propeller fan make with the plane of rotation, measured at a prescribed point on each blade. Unit: Degrees

- Fan Scroll: Convolute housing in which a centrifugal (blower) fan operates.

- Fan Stack: An extended fan cylinder whose primary purpose is to achieve elevation of the discharge plume.

- Fill: The portion of the cooling tower which constitutes its primary heat transfer surface. Also referred to as “packing”.

- Float Valve: A valve which is mechanically actuated by a float. Utilised on many cooling towers to control make-up water supply.

- Forced Draft: Refers to the movement of air under pressure through a cooling tower. Fans of forced draft towers are located at the air inlets to “force” air through the tower.

- Heat Load: Total heat to be removed from the circulating water by cooling tower. Units kW’s

- Hot Water Temperature (HWT): Temperature of circulating water entering the cooling towers distribution system. Unit: ℃ Symbol: HW

- Induced Draft: Refers to the movement of air through a cooling tower by means of an induced partial vacuum. Fans of induced draft towers are located at the air discharges to “draw” air through the tower.

- Liquid-to-Gas Ratio: A ratio of the total mass flows of water and dry air in a cooling tower. (See Total Air Rate & Total Water Rate) Symbol: L/G.

- Louvers: Plastic assemblies installed at the air inlet face of a cooling tower to control water splash out and/or promote uniform air flow through the fill.

- Make-Up: Water added to the circulating water system to replace water lost by evaporation, drift, windage, blowdown, and leakage. Unit: l/s or Kg/s

- Nozzle: A device used for controlled distribution of water in a cooling tower. Nozzles are designed to deliver water in a spray pattern either by pressure or by gravity flow.

- Plenum Chamber: The enclosed space between the drift eliminators and the fan in induced-draft towers, or the enclosed space between the fan and the fill in forced-draft towers.

- Plume: The effluent mixture of heated air and water vapor (usually visible) discharged from a cooling tower.

- Range: Difference between the hot water temperature and the cold water temperature

(HW – CW = R)

- Recirculation: Describes a condition in which a portion of the tower’s discharge air re-enters the air inlets along with the fresh air. Its effect is an elevation of the average entering wet-bulb temperature compared to the ambient.

- Total Air Rate: Total mass flow of dry air per hour through the tower.

- Total Water Rate: Total mass flow of water per hour through the tower.

- Wet Bulb Temperature: The temperature of the entering or ambient air adjacent to the cooling tower as measured with a wet bulb thermometer.

- Tower Pumping Head (TDH): The static lift from the elevation of the basin curb to the center line elevation of the distribution system inlet plus the total pressure (converted to metres head of water) necessary at that point to effect proper distribution of the water to its point of contact with the air. Unit: m of water

- Water Loading: Circulating water rate per horizontal square metre of fill-plan area of the cooling tower.

- Water Rate: Mass flow of water per square metre of fill-plan area of the cooling tower per hour.

- Wind Load: The load imposed upon a structure by a wind blowing against surface.