| Material | Corrosion Resistance | Mechanical Strength | Fire Resistance | Cost | Typical Use Case | Notes |

| Galvanised Steel | ⭐ – Low in coastal/acidic areas | ⭐⭐⭐⭐ – Good | ⭐⭐⭐⭐ – Excellent | £ (Low) | Budget installs, indoor, mild climates | Zinc coating vulnerable to scratches, sacrificial layer |

| Coated Mild Steel | ⭐⭐ – Moderate (coating-dependent) | ⭐⭐⭐⭐ – Good | ⭐⭐⭐⭐ – Excellent | £–££ (Low-mid) | General industrial, HVAC rooftops | Needs regular inspection; coating integrity critical |

| 304 Stainless Steel | ⭐⭐⭐⭐ – Good in most environments | ⭐⭐⭐⭐ – High | ⭐⭐⭐⭐ – Excellent | £££ (Mid-high) | Food, pharma, light industrial | Susceptible to chlorides (tea staining) |

| 316 Stainless Steel | ⭐⭐⭐⭐⭐ – Excellent in chlorides | ⭐⭐⭐⭐ – High | ⭐⭐⭐⭐ – Excellent | ££££ (High) | Marine, chemical, outdoor exposure | Standard high-grade spec for harsh conditions |

| Duplex Stainless (2205) | ⭐⭐⭐⭐⭐ – Superior to 316 | ⭐⭐⭐⭐⭐ – Very high | ⭐⭐⭐⭐ – Excellent | ££££ (High+) | Pulp/paper, offshore, acidic processes | High strength-to-weight ratio; more brittle to weld |

| Super Duplex (2507) | ⭐⭐⭐⭐⭐⭐ – Extreme resistance | ⭐⭐⭐⭐⭐ – Exceptional | ⭐⭐⭐⭐ – Excellent | £££££ (Very High) | Desalination, subsea, refinery plants | Limited suppliers; needs expert fabrication |

| 904L Stainless Steel | ⭐⭐⭐⭐⭐ – Excellent in acids | ⭐⭐⭐⭐ – High | ⭐⭐⭐⭐ – Excellent | £££££ (Very High) | Sulphuric acid, chemical processing | Overkill for most cooling towers |

| Alloy 20 | ⭐⭐⭐⭐⭐ – Extreme acid resistance | ⭐⭐⭐⭐ – High | ⭐⭐⭐⭐ – Excellent | £££££+ (Very High) | Fertiliser, sulphuric acid handling | Specialised, low availability |

| Titanium (Grade 2 or 5) | ⭐⭐⭐⭐⭐⭐ – Near-total corrosion immunity | ⭐⭐⭐⭐⭐ – Very high | ⭐⭐⭐⭐ – Excellent | ££££££ (Extreme) | Nuclear, desalination, ultra-aggressive sites | Lightweight, inert, but cost and fabrication are limiting |

GRP Casing Variants

GRP used in cooling tower casings varies significantly in quality and performance, depending on the formulation, manufacturing method and reinforcement. Like steel, it is not a single standardised product.

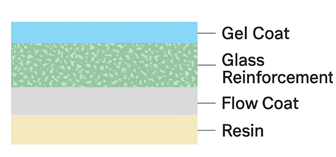

GRP cooling tower casings incorporate four layers:

Gel Coats – How do they help?

These pigmented, UV-resistant coatings are applied during moulding to:

- Improve surface finish

- Provide UV protection

- Enhance chemical resistance

- Reduce fibre blooming and surface micro-cracks

Quality GRP casings should have:

- UV-stabilised gel coat, often 0.3–0.5 mm thick

- Colour-fast additives to prevent yellowing or fading

- Class 1 fire-retardant gel coats (BS 476 or equivalent)

Glass reinforcement (Structural Core Layer)

Forms the core structural strength of the GRP laminate.

Key Characteristics:

- Typically made from E-glass fibres (chopped strand mat, woven roving, or combinations).

- Embedded into resin to form a composite matrix.

- Fibre content typically 30–40% by weight.

- Provides tensile strength, impact resistance, and dimensional stability.

- Layering and orientation can be tailored for load-bearing requirements.

The more layers and better the fibre distribution, the stronger and more durable the structure.

Resin Matrix (Binder Layer / Matrix Throughout)

The purpose of this layer is to provide the thermosetting binder that holds the glass fibres together, creating the composite material.

GRP variants and resin systems:

It is possible to find four main types of resin in GRP cooling tower casing materials.

| Type | Description | Typical Use Case |

| Orthophthalic Polyester Resin | Standard, economical GRP resin; moderate corrosion and UV resistance | HVAC, light industrial use |

| Isophthalic Polyester Resin | Better chemical resistance and strength than orthophthalic | Industrial cooling towers |

| Vinylester Resin | Excellent chemical and temperature resistance; more flexible than polyester | Chemical plants, high-chloride areas |

| Epoxy Resin | Very high mechanical strength and chemical resistance; rarely used in casings | High-end aerospace or marine structures |

Fibre Content (Glass-to-Resin Ratio)

The fibre-to-resin ratio (typically measured by weight %) is critical to GRP’s strength and performance. 30-40% is typical within the industry:

| Fibre Content by Weight | Typical Quality | Implication |

| 20–25% | Low – may be brittle or resin-rich | Poor strength, prone to cracking |

| 30–40% | Standard industry quality | Balanced mechanical properties |

| 50%+ | High-performance | Used in structural GRP, very strong and rigid |

Flow Coat (Internal Surface Finish)

Applied to the internal surfaces of the GRP casing, this resin-rich finishing layer enhances cleanliness, provides a sealed surface, and improves overall appearance.

Key Characteristics:

- Applied by brush or spray after moulding is complete.

- Typically made from the same resin system as the main laminate (no glass fibre).

- Improves hygiene, smoothness, and chemical resistance.

- May include pigments (e.g., grey or white) for visual inspection or compliance.

There are several other considerations when choosing a GRP cooling tower, including the Fire retardancy, moulded thickness and manufacturing method amongst others:

Other Quality Factors to Consider with GRP casings:

| Specification | Relevance | Reference |

| Fire Retardancy (BS 476 Part 7, EN 13501-1, ASTM E84) | Critical for compliance in plant rooms or indoor applications | EN 13501-1:2018, BS 476-7:1997, ASTM E84-20 |

| UV Stabilisers | Essential for outdoor exposure (>10 years) | Composites UK (2023), Ashland Resin Guide (2023) |

| Glass Type (E-glass vs S-glass) | E-glass is standard; S-glass offers higher tensile strength | Owens Corning Glass Fibre Handbook; ASTM D2344 |

| Moulded Thickness (typically 3–6 mm) | Affects panel strength and thermal resistance | ISO 527-4:2021, Plasticon GRP Design Guide |

| Manufacturing Method (Hand lay-up, RTM, Vacuum infusion) | Affects fibre consistency, void content, and repeatability | Reichhold Composites Processing Manual; Composites UK Manufacturing Best Practice |

| Surface Hardness (ASTM D2583, ISO 2039-1, BS EN ISO 2039-1) | Indicates degree of cure and quality of GRP surface; higher values reflect better consolidation | ASTM D2583-13, ISO 2039-1:2001, BS EN ISO 2039-1:2003 |

Basis for comparison

This article compares the steel variants with the GRP options across

- Capital Cost

- Mechanical strength

- Corrosion resistance

- Life span

- Lifetime Cost

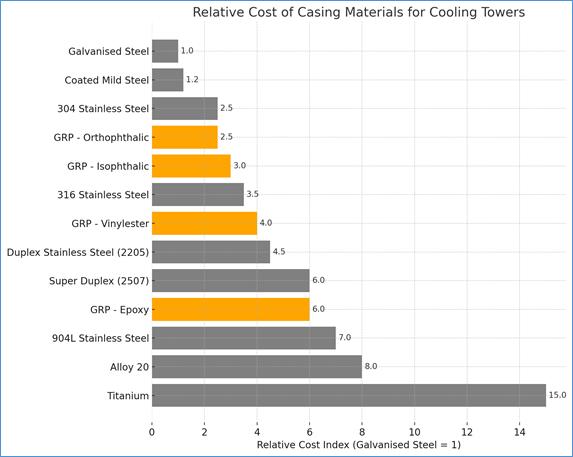

Relative Cost of Casing Materials

Chart Summary:

- The lowest-cost options are galvanised and coated mild steel, making them attractive for budget-sensitive applications with low exposure to corrosion.

- 304 and 316 stainless steels occupy the mid-to-high cost bracket, justified by improved corrosion resistance and lifespan.

- GRP variants (Orthophthalic through to Epoxy) fall within a moderate cost range (comparable to or just below 316), with costs increasing with resin performance. Vinylester and Epoxy GRP are significantly more expensive than basic polyester types due to enhanced chemical resistance and manufacturing complexity.

- Titanium and exotic alloys (Alloy 20, 904L) command premium pricing, suitable only in cases where extended service life and zero corrosion tolerance are critical.

Key Insight:

GRP can provide a cost-effective middle ground between basic steel and high-grade stainless alloys, especially in corrosion-critical environments where lifecycle value outweighs upfront cost.

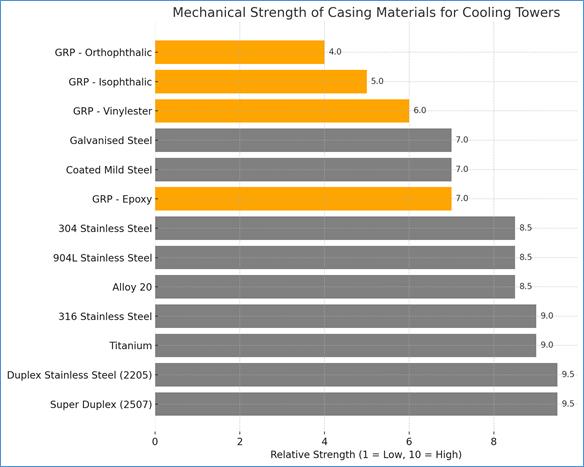

Mechanical Strength of Casing Materials

Chart Summary:

- Steel variants, particularly Duplex and Super Duplex, exhibit consistently high mechanical strength, making them suitable for large towers, wind-exposed sites, and structural load-bearing applications.

- GRP strength varies significantly:

- Orthophthalic GRP ranks lowest, suitable for low-stress applications.

- Isophthalic and Vinylester GRP offer improved strength, with Epoxy GRP achieving near parity with mild steel in some cases due to its superior fibre bonding.

- Titanium performs strongly in both strength and corrosion resistance, justifying its use in extreme environments.

Key Insight:

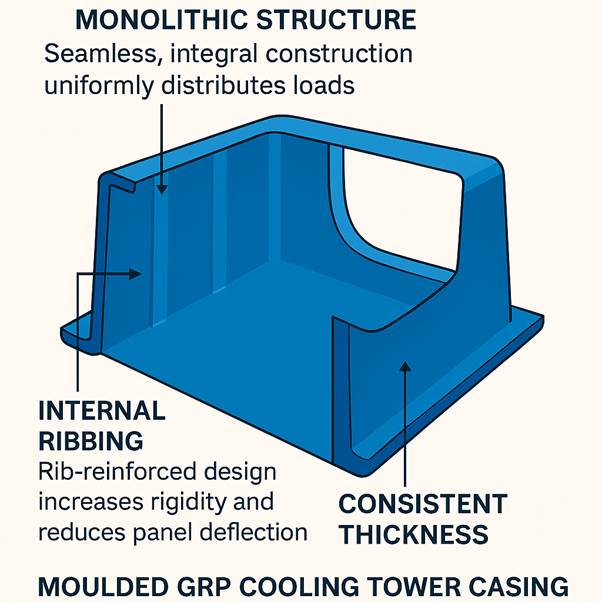

Where structural strength is a primary concern, metal casings still lead. However, high-grade GRP with correct reinforcement and ribbing can meet requirements in packaged or modular towers when properly engineered. In most factory assembled cooling towers, especially those <10m tall, well moulded GRP casings provide sufficient mechanical strength for all functional requirements.

When considering structural strength in GRP casing the below graphic shows the key considerations.

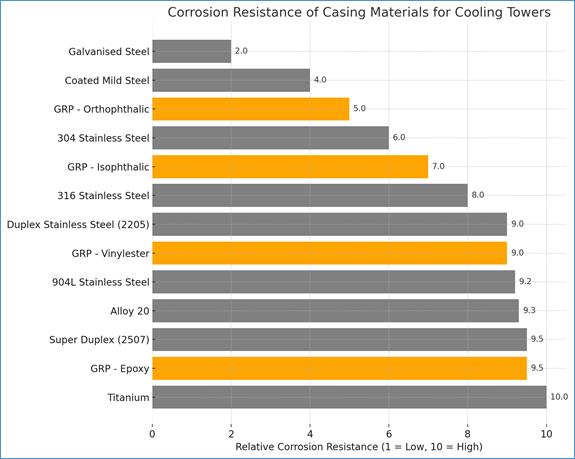

Corrosion Resistance of Casing Materials

Chart Summary:

- The clear leaders are Titanium, Super Duplex, and Epoxy/Vinylester GRP, offering exceptional resistance to seawater, aggressive chemicals, and atmospheric exposure.

- 304 stainless steel is adequate for many environments but can suffer in chloride-laden or acidic atmospheres.

- Galvanised and coated mild steels have the lowest corrosion resistance — suitable only for indoor or low-corrosion environments.

- Among GRP types, Vinylester and Epoxy resins outperform Orthophthalic and Isophthalic, which are more susceptible to hydrolysis and chemical degradation.

Key Insight:

Corrosion resistance is the primary driver for selecting GRP over steel. Specifying the right resin (especially Vinylester or Epoxy) is crucial to ensuring long-term performance.

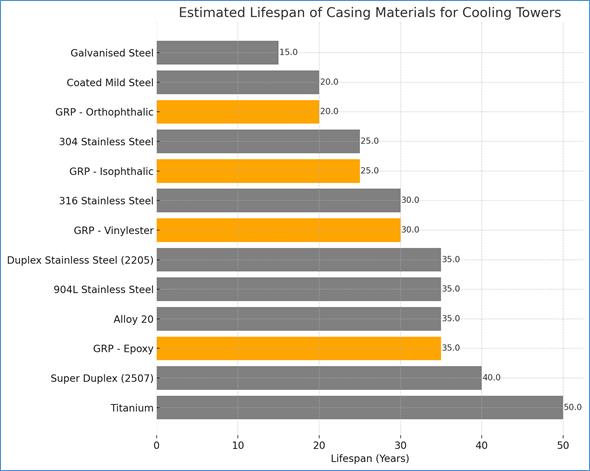

Estimated Lifespan of Casing Materials

Chart Summary:

- Titanium and Super Duplex stainless steel offer the longest service life (40-50+ years), with minimal degradation under harsh conditions.

- Standard stainless steels (304/316) and Vinylester/Epoxy GRP offer solid 25-35 year lifespans when well maintained.

- Coated mild steel and orthophthalic GRP tend to have shorter service lives due to coating breakdown and chemical vulnerability.

- Proper maintenance, UV protection, and mechanical integrity are major factors in achieving upper-end lifespan projections.

Key Insight:

Well-formulated GRP, especially with vinylester or epoxy resin and proper gel/flow coats, can offer a reliable 25–35-year service life, comparable to mid-range stainless steel – if installed and maintained correctly.

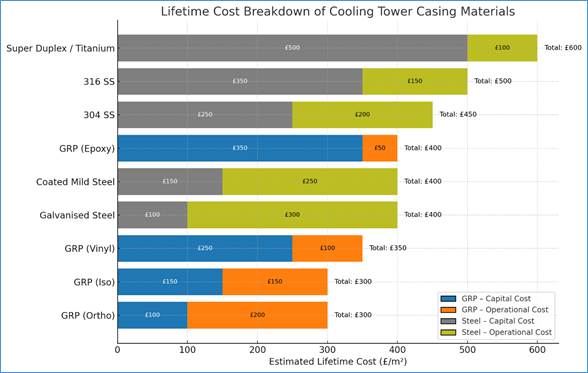

Lifetime Cost of cooling tower casing materials

The above chart compares the lifetime costs of different casing materials over a typical 30-year period.

While the chart shows stainless steels like 316 and 304 may appear more expensive over 30 years, this assumes ideal maintenance and full-life performance from galvanised and coated steel, which is rarely the case in aggressive or poorly ventilated environments. When factoring in the real risk of corrosion, rework, and replacement, stainless and GRP solutions often outperform lower-cost materials in total cost and reliability.

Often, full replacement of a galvanised or coated steel tower comes before the 30-year mark (typically 20-25 years); therefore, consideration should be given to this when comparing different casing materials. Water treatment costs are also higher for galvanised steel due to zinc sensitivity to pH, hardness and chlorine and higher bleed-off requirements to protect the coating.

Key takeaways for asset owners:

- Galvanised and mild steel look cheap at the start, but they rust, need repainting, and often get replaced early. Over 30 years, they’re usually the most expensive option overall.

- Stainless steel (316) and GRP (vinylester) offer the best value, with fewer interventions, longer life, and more predictable upkeep.

- GRP systems are chemically inert, so they don’t interact with water treatment regimes the way metal casings do. That saves on dosing costs and risk.

- Epoxy GRP and Titanium sit at the high end of the market, ideal for corrosive environments or sites with minimal maintenance access.

Water Chemistry

The water chemistry has a significant impact on the lifespan of the cooling tower casing; therefore should be given careful consideration when choosing the material type for your cooling tower casing. The table below compares the different material types and how each material behaves to:

- Water treatment sensitivity

- General corrosion resistance

- Chloride resistance

| Material | Water Treatment Sensitivity | General Corrosion Resistance | Chloride Resistance |

| Galvanised Steel | High – Sensitive to pH, hardness, chlorine. Requires tight control. | Low – Zinc coating sacrificial, prone to white rust, under-deposit corrosion | Poor – Chlorides accelerate zinc loss and underfilm corrosion |

| Coated Mild Steel | Moderate – Coating protects steel, but damage or age leads to rapid corrosion | Moderate – Dependent on coating quality and integrity | Low–Moderate – Coating breakdown exposes vulnerable base metal |

| 304 Stainless Steel | Moderate – Requires control of chloride levels (<200 ppm) | Good – Passive layer resists general corrosion | Limited – Susceptible to pitting >200 ppm chlorides |

| 316 Stainless Steel | Low – More tolerant of varied water quality | Very Good -Molybdenum improves corrosion protection | Good – Tolerates up to ~1000 ppm chlorides, but still finite |

| Super Duplex / Titanium | Very Low – Highly tolerant; suitable for aggressive water | Excellent – Inert in almost all cooling water conditions | Excellent – Titanium tolerates >10,000 ppm chlorides |

| GRP (Orthophthalic) | Moderate – Chemically resistant but less tolerant of oxidisers like chlorine | Moderate – Resin type limits long-term exposure in harsh systems | Limited – Can degrade in high chloride or oxidiser environments |

| GRP (Isophthalic) | Low – Improved chemical resistance vs. orthophthalic | Good – Handles most standard industrial water chemistries | Moderate – Tolerates moderate chloride levels (~1000 ppm) |

| GRP (Vinylester) | Very Low – Highly chemically resistant, inert to most cooling tower chemistries | Excellent – Widely used in chemical tanks and scrubbers | Good -Very Good -Stable under high chloride and oxidiser exposure |

| GRP (Epoxy) | Very Low – Excellent for aggressive water or condensate return | Excellent – Highly stable structure and adhesion | Very Good – Excellent for marine, brine, or salt-laden conditions |

Key Insights:

- Galvanised and coated steel are the most sensitive to water treatment, they demand tighter control and incur higher chemical costs to preserve life.

- 304 stainless offers reasonable corrosion resistance, but still has chloride limits; 316 stainless is significantly better for industrial water.

- GRP materials, especially vinylester and epoxy, are chemically inert and do not corrode, a major advantage in aggressive or variable water conditions.

- Titanium and Super Duplex are the gold standard for corrosion performance but usually only justifiable in extreme cases due to cost.

Conclusion

So, after considering all these factors. Who is the ultimate winner? As always,..it depends. When it comes to selecting a cooling tower casing material, there is no universally “better” option, only the right material for the right environment.

Steel, particularly coated and stainless variants, offers high mechanical strength, excellent fire resistance, and proven long-term durability when properly maintained. It remains a favoured choice in structural applications, rooftop installations, and where load-bearing or high-temperature resistance is critical.

On the other hand, GRP brings clear advantages in environments where corrosion, chemical exposure, or access constraints are the driving concerns. Modern GRP systems, especially those using vinylester, UV-stabilised gel coats, and correct fibre reinforcement, can match or exceed the performance of mid-tier stainless steel in many corrosive applications, while offering simpler handling and reduced maintenance.

Ultimately, the optimal choice depends on your operating environment, lifecycle expectations, and budget priorities. Where possible, engage early with a technical partner who understands not just the materials, but how they interact with your system, site constraints, and process risks.

Contact us now for more information and ensure you are informed before making such an important decision such as replacing cooling system on site!