As I mentioned in my recent article comparing GRP with steel casing materials, cooling towers typically last between 20 and 35 years. Over that time, you’ll expect to replace consumables like packing, drift eliminators and louvers, and occasionally overhaul the fan and motor. But the one part most often neglected is the tower casing itself.

As part of our refurbishment business, we are often asked to investigate corrosion and leaks within cooling towers that are past their best, resulting in options for coatings and lining of the casing, be it the sump, or the entire internal and external casing.

GRP (Glass-Reinforced Plastic) lining, PU (Polyurethane) coatings, and Epoxy resin systems are three common approaches to refurbishing steel cooling towers that have suffered corrosion or leakage. Each has advantages and trade-offs depending on the severity of the damage, operating conditions, and long-term priorities.

I find the key consideration when clients approach us for coating work is understanding how long they would like the cooling tower to last. GRP comes at a cost, and PU and Epoxy certainly have their place in the market, but it’s not possible to get the benefits of GRP at the cost of PU or Epoxy. A cooling tower is a comparably harsher environment than, say, a potable water tank, and that should be considered when deciding which way to go.

Full disclosure: Vistech don’t offer PU or Epoxy resin coatings as a solution for the interior casing of cooling towers. Not because they don’t have valid use cases, but because we prefer to offer long-term, low-maintenance solutions. GRP lining gives us the confidence to issue 10-year guarantees, and sleep at night.

GRP Lining Process

Choosing the Best Option for Your Site

Steel cooling towers are vulnerable to corrosion and leakage as they age. When refurbishment is more cost-effective than replacement, the most common options are:

- GRP (Glass-Reinforced Plastic) lining

- PU (Polyurethane) coating

- Epoxy resin coating

This guide compares the three from a buyer’s perspective, focusing on long-term performance, downtime, cost, and maintenance.

What Are GRP, PU, and Epoxy Coatings?

- GRP Lining is a fibreglass laminate built with resin and glass mat. Once cured, it forms a rigid structural lining bonded to the steel casing.

- PU Coating is a liquid-applied polyurethane membrane. It cures into a flexible, waterproof barrier suited to general corrosion protection.

- Epoxy Coating is a hard-setting two-part coating system. It bonds well and offers good chemical resistance but does not reinforce damaged substrate.

Comparison Table

| Factor | GRP Lining | PU Coating | Epoxy Resin Coating |

| Best for | Heavily corroded or structurally weakened sumps and tanks requiring reinforcement | Light corrosion, pinhole sealing | Moderate corrosion on intact substrates |

| Lifespan | 15–25 years with correct resin | 5–10 years typical | 5–12 years depending on formulation |

| Cost | Higher initial cost due to material and labour | Lower cost | Moderate cost |

| Downtime for application | Longer cure and installation time (1–3 days depending on complexity) | Same-day or next-day turnaround | 1–2 days typical |

| Structural benefit | Yes, reinforces steel structure | No, protective only | No, protective only |

| Leak sealing | Effective on holes and cracks | Suitable for minor surface leaks | Seals porosity, not suitable for active leaks |

| Chemical resistance | Excellent with appropriate resin (e.g. vinyl ester for aggressive water) | Good; depends on formulation, may degrade faster under extreme pH or oxidising biocides | Good to excellent (resin-dependent) |

| Maintenance | Long-life, easy to inspect and patch | May require full recoating if breached | Can chalk or become brittle over time |

| Fire performance | Fire-retardant resins available | Limited | Available in fire-rated systems |

| Coating thickness | 3–6 mm | 0.5–1 mm | 0.3–0.8 mm typical |

| Surface preparation | Requires abrasive blasting or heavy grinding | Light profiling or abrasive clean | Requires clean, well-prepared surface |

| Bond to substrate | Strong mechanical bond, but delamination possible if poorly prepared | Excellent adhesion if surface is properly primed | Excellent if surface is dry and clean |

Total Cost of Ownership over 10 years

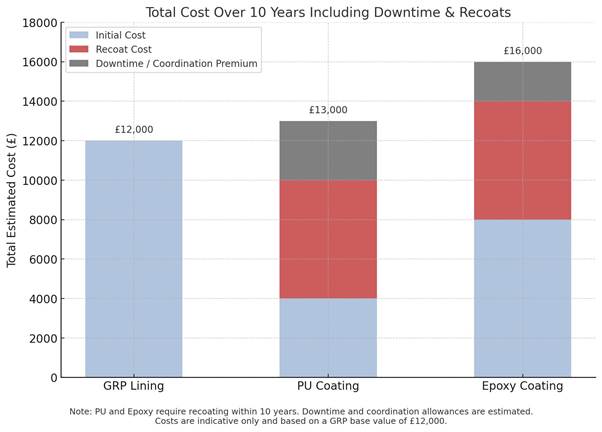

While PU and Epoxy coatings may seem attractive on price, the need for regular reapplication means their long-term costs can rival or even exceed GRP without the structural benefits or guarantees.

The chart below compares estimated lifetime costs over a typical 10-year period for a typical cooling tower sump coating with approx. dimensions 3.6m (l) x 2.5m (w) x 0.6m (h):

When to Choose GRP Lining

Choose GRP if:

- The tower has severe corrosion or physical damage.

- You want structural reinforcement as well as corrosion protection.

- Long-term durability and minimal future maintenance are priorities.

- You’re willing to accept a slightly longer shut down for a more permanent solution.

When to Choose PU Coating

Choose PU if:

- You’re managing light corrosion and need a fast turnaround.

- Budget is limited and the asset is not critical long-term.

- You need a moisture-tolerant application that’s forgiving of marginal surface prep.

When to Choose Epoxy Coating

Choose Epoxy if:

- The steel is intact but showing signs of moderate corrosion.

- You need strong adhesion and chemical resistance but not structural reinforcement.

- You want a finish that is hard and abrasion-resistant.

- You’re refurbishing tanks or components exposed to mild chemicals or thermal variation.

Decision Guide: Buyer Priorities

| Your Priority | Recommended Option |

| Long-term durability | GRP lining |

| Minimal operational downtime | PU coating |

| Moderate corrosion, intact steel | Epoxy coating |

| Structural reinforcement | GRP lining |

| Budget-conscious refurbishment | PU or Epoxy coating |

| Ease of visual inspection | GRP lining |

| Fire performance | GRP or Epoxy with rated resin |

| Harsh water chemistry | GRP with vinyl ester resin |

Final Comparison Before You Decide

GRP, PU, and Epoxy coatings each have their place in cooling tower refurbishment. GRP offers a permanent, structural fix with long-term confidence. PU is the fastest and least disruptive. Epoxy sits in the middle, tougher than PU, but without the reinforcement of GRP.

Your decision should be based on:

- The condition of the steel substrate

- How long you want the refurbishment to last

- Tolerance for downtime and maintenance

- Water chemistry and operating environment

- Total cost of ownership, not just day-one pricing

Not sure which route is right for your tower? Send us a few photos or arrange a site survey and we’ll help you weigh up the options and make a confident decision.