Consistency of product output in batch or continuous manufacture is rarely a primary process problem. It is usually a cooling system problem: unstable temperatures, variable flow, uneven distribution, and manual control that cannot keep up when multiple users all needing cooling demand at once.

Designing the full process cooling system with distribution, controls, and operating philosophy in mind is how cooling becomes a predictable utility rather than a daily firefight.

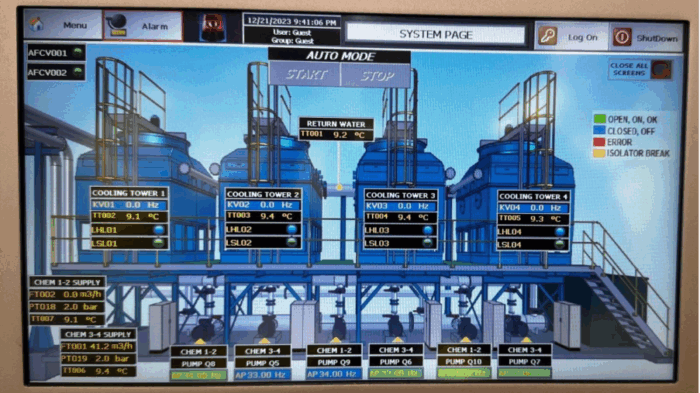

One of our most recent design studies had an upgrade brief, the objectives were explicit: certainty in production output, capacity for eight vessels operating simultaneously, improved distribution and pressure stability, progressive automation, energy efficiency, and reliability. The outline design anchors this at 3.28 MW, 94 m³/h, 55 °C to 25 °C, with < 3.0 bar system pressure drop and 20 % capacity margin.

- Why product consistency is a cooling system outcome?

- Water distribution as the hidden variable in manufacturing quality

- Automation and control that genuinely stabilises temperature

- Hydraulic architecture: ring mains, bypasses, minimum circulation

- Designing reliability into the system

- What to specify before the design is frozen

Why Product Consistency Is a Cooling System Outcome

If you want consistent product, you need consistent heat removal. That requires repeatable flow, temperature, and pressure at each and every part of your manufacturing process even when demand changes rapidly.

Installed cooling capacity alone does not guarantee this.

Common failure modes include:

- Differential pressure collapse when multiple primary process machinery require cooling simultaneously

- Fixed-speed pumps fighting control valves

- Uneven distribution causing a “first-come-first-served” flow

- Manual overrides creeping in to “get through today” through a “quarter turn here, and a quarter turn there”

The objective is to remove distribution and pressure instability whilst not presenting a problem for exapansion in the future reflects the correct approach.

Water Distribution: The Hidden Variable in Manufacturing Quality

Uneven Flow Means Uneven Heat Transfer

For example, two identical vessels/extruders/compressors supplied from the same cooling system can behave very differently if distribution is not engineered correctly. Even with a stable supply temperature, variable flow creates variable heat transfer.

Typical symptoms include:

- Manual valve balancing becoming normal practice

- Noisy, erosive pipework on some branches

- Legacy parts of the primary process starved of flow when newer equipment starts

- Manufacturing variability that correlates with production load

Automation and Control That Actually Stabilises Temperature

Automation is not an HMI screen. It is a control philosophy that ensures the system behaves consistently across the full load range.

What Effective Control Looks Like

- Variable-speed pumping to stabilise system differential pressure

- Central temperature control rather than multiple competing local loops

- Minimum circulation protection to maintain heat rejection stability

- Instrumentation that supports decision-making, not just trend logging

Our design’s incorporates PLC control, VSD-driven pumps and fans, system pressure and temperature sensors, flow bypass to protect minimum tower circulation etc.. This is the foundation of progressive automation and where Vistech lead in designing world class cooling systems.

Avoiding Control Conflict

One of the most common design errors is allowing aggressive local control valves to fight a rigid plant.

Control hierarchy matters:

- Pumps stabilise system pressure and flow

- Heat rejection plant stabilises temperature

- Local valves perform trim, not firefighting

If that order is reversed, tuning becomes endless and instability inevitable.

Hydraulic Architecture: Ring Mains, Bypasses, and Minimum Circulation

Stable cooling systems share common architectural traits:

- Distribution mains sized for future duty, not today’s average

- Branch arrangements that avoid dead-legs and shortcuts

- Bypass paths to maintain minimum pump and tower flows

Each system should have a target bar total pressure drop at duty and use duty/standby pumps all on VSDs. This keeps the network hydraulically “stiff” while allowing energy consumption to fall as demand reduces.

Reliability by Design, Not Assumption

Manufacturing consistency collapses fastest when reliability is assumed rather than engineered.

Reliability includes:

- Materials selection that resists performance decay

- Maintainable strainers and valves

- Commissioning under representative load combinations

- Operator training that prevents drift back to manual control

By explicitly addressing phased installation, zero production downtime during changeover, and structured commissioning and training, it ensures reliability across the manufacturing processes. These elements are as critical as the mechanical design itself.

What to Specify Before You Freeze the Design

If consistency matters… as it should for all UK manufacturing, design must be confronted early. Where data is incomplete, a FEED-level survey and modelling exercise is essential.

Minimum specification inputs include:

- Maximum credible simultaneous load case

- Required flow and allowable pressure drop per user

- Supply and return temperature requirements by season

- Fouling factors and water quality assumptions

- Defined control hierarchy and alarm philosophy

- Measurable commissioning acceptance criteria

Without these, performance risk is simply deferred – not removed.

Next steps…

- Commission a FEED or site survey to remove uncertainty

- Request a piping layout/P&ID review

- Run a controls workshop to define automation boundaries and priorities

FAQs

Why does uneven cooling distribution cause manufacturing variability?

Because flow variation directly affects heat transfer, even at constant temperature.

Do I need a ring main or can valves balance the system?

Valves alone cannot correct systemic pressure gradients under variable load.

What should pumps control – flow, pressure, or temperature?

Typically pressure, allowing temperature to be controlled at system level.

How do VSDs improve stability?

They dampen demand changes and prevent pressure collapse.

How much spare capacity should be allowed?

Typically 15–25 %, depending on growth and operational risk.