When planning maintenance and budgeting for industrial cooling towers, one pressing question often comes up:

How long does heat‑transfer packing last, and what will replacement cost?

This matters because degraded packing can dramatically reduce cooling efficiency, increase energy consumption, create health risks, and escalate downtime. With hundreds of successful refurbishments completed across the UK, Vistech Cooling Systems has the insight to answer this clearly backed by our 50+ year experience in this industry niche.

In this article, you’ll find typical service lives, cost factors (materials, labour, safety, compliance), plus what to expect during replacement all in plain language for plant engineers, project managers, and procurement teams.

1. Typical Lifespans of Heat Transfer Packing

Heat-Transfer Packing (Fill)

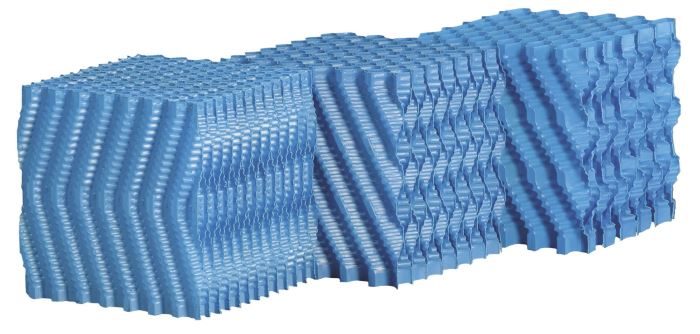

High-quality heat transfer packing typically made of PVC or polypropylene, typically last 3 to 7 years, depending on the material, operating conditions, and maintenance regimen.

Modern pack materials (PP or PVC) offer high heat-transfer efficiency, reducing required tower size by around two-thirds. They’re UV‑, chemical‑, and bacteria‑resistant, and lighter than older wooden designs, making them easier to clean and replace.

A typical well-maintained cooling tower can deliver 20 to 50 years of service depending on its materials of construction, during which multiple replacement cycles of packing are expected.

2. Why Degradation Occurs and What to Watch For

- Fouling, scaling & biofilm: Mineral deposits, suspended solids, and biological growth block air and water pathways, reducing surface area, and choking airflow. This leads to higher pressure drop, reduced cooling performance, and increased energy use.

- UV, chemicals & mechanical wear: Exposure to sunlight, oxidising biocides, or harsh cleaning methods can make PVC/PP packing brittle, warped, or cracked, causing sections to collapse or detach.

- Packing integrity issues: Watch for sagging or collapsed blocks, brittleness, blocked flutes, unusual pressure drops across the fill, or uneven water distribution. Any of these signs indicate cleaning is no longer effective and full replacement may be required.

3. Cost Considerations: Materials, Labour, Safety & Compliance

Packing & Delivery

High-performance modular packing blocks or grids (PP/PVC) are easier to handle and install. Costs vary by size, material, and supplier.

Skilled Labour

Technician time is needed to remove old pack, assess tower internals, clean where possible, and fit the new units safely and effectively.

Safe Access Flooring

Installing GRP open‑mesh safe flooring beneath the pack ensures safe access for inspection and maintenance, protecting staff and reducing component damage.

Legionella Mitigation & Compliance

Anti‑legionella measures such as drift eliminators and pack materials designed to minimise bacterial growth help with compliance to ACOP L8 and HSG 274.

| Option | What’s Included | Typical Cost Range* (UK, excl. VAT) | Best For |

|---|---|---|---|

| Supply-Only Packing | Delivery of modular PP/PVC fill blocks, sized for your tower. | £200 – £400 per m² | Sites with in-house maintenance teams who can install themselves. |

| Supply + Install | Packing supply, removal of old blocks, fitting of new, labour. | £400 – £600 per m² | Standard refurbishments where downtime needs to be minimised. |

| Full Refurbishment with GRP Flooring | Packing supply + install, safe access flooring, internal clean, inspection report, compliance documentation. | £600 – £1,000 per m² | UK sites serious about ACOP L8/HSG 274 compliance and long-term reliability. |

Notes for Buyers

- Access & logistics: If towers require scaffolding, cranage, or confined-space entry, costs rise.

- Materials: PP is slightly more expensive but lasts longer under high temperatures or aggressive water chemistry.

- Downtime planning: Budget for lost production during packing replacement unless works are scheduled in planned shutdowns.

- Compliance: Full refurb packages ensure alignment with ACOP L8 / HSG 274, reducing Legionella risk.

*Estimations based on standard criteria prices can vary. Please contact us for a full quotation

5. Our Perspective: Vistech’s Approach to Real-World Projects

- We’ve refurbished thousands of towers across UK industrial manufacturing site with some reaching 20–25 years in service.

- GRP flooring installations significantly enhance on-site safety and reduce damage during maintenance activities, resulting in longer component life and fewer replacement cycles.

- Modular PP/PVC packs simplify handling and cleaning, speeding up maintenance and cutting downtime.

- Tailored cleaning and maintenance contracts aligned with ACOP L8 and HSG 274 include detailed inspections of drift eliminators, nozzles, heat-transfer surfaces, and documentation with photos for compliance and audit purposes.

If your cooling tower or drift eliminator is over 3–7 years old, or your packing hasn’t been refreshed in 10+ years, we recommend scheduling a full inspection. Speak to Vistech’s engineering team for a tailored quote, condition assessment, and replacement roadmap that ensures safety, efficiency, and regulatory compliance.