Industrial cooling towers come in several configurations, but most UK manufacturing sites with existing towers will have one of these three types:

What Are Induced-Draft Cooling Towers?

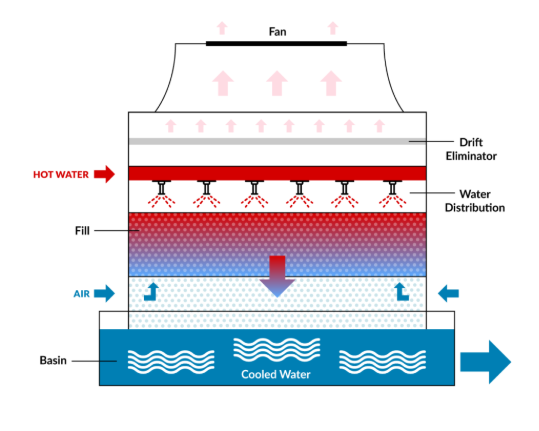

These are the most common type in industrial applications. A fan is mounted at the top, drawing air upwards through the inlet louvers located on the sides, towards the bottom of the tower.

Key Benefits of Induced-Draft Design

This arrangement creates lower air velocities on the intake and high velocities on the discharge, reducing recirculation, where discharged warm air is drawn back into the air intake reducing efficiency. The lower velocities also promote less airborne material being drawn into the system so a positive for system cleanliness. Induced draft towers have axial fans which can be noisier than centrifugal fans found on many forced draught towers. Efficient and compact, they offer good cooling performance and are often simple to service.

Why Choose Forced-Draft Towers?

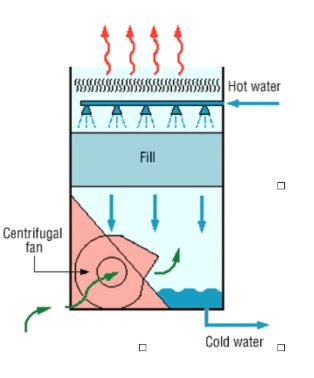

As per their name suggests, these towers use a fan at the air inlet on the side to push air through the tower, which discharges through the top of the tower

Axial vs. Centrifugal Fans

There are options for fan types, from fixed and belt driven axial fans through to centrifugal fans which draw air into the centre of the fan and pushes it out perpendicular to the intake. Forced draft towers can be quieter than their induced draft cousins and are good where there are physical restrictions or if the tower is located indoors and requires ducting as they are typically only drawing on one side of the tower.

Understanding Crossflow Cooling Towers

Maintenance Challenges & Pack Arrangements

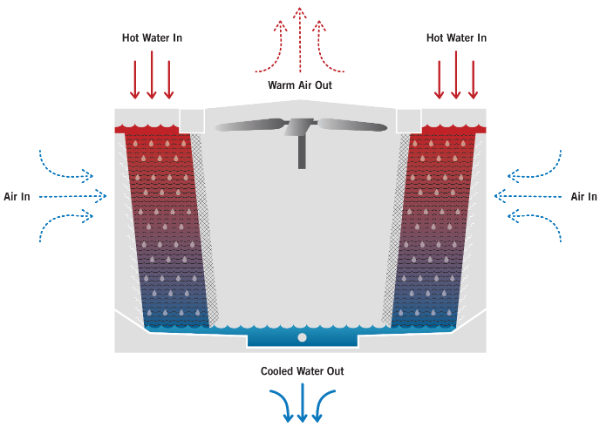

Whereas Induced and Forced draft towers are categorised as counterflow where the air travels in a counter direction to the water, in a crossflow tower, water flows vertically while air moves horizontally. Fans are located at the top of the tower and air is drawn through the side, across the heat transfer surface and up through the fan.

Maintenance Challenges & Pack Arrangements

As mentioned above these arrangements can be difficult to maintain, particularly when it comes to cleaning, depending on the pack arrangement but can be suitable for large industrial applications.

Frequently Asked Questions

To wrap up, it’s worth pausing to ask:

- Is your existing cooling tower optimised for today’s efficiency and environmental targets?

- Could a different tower configuration or a bespoke solution deliver lower running costs and reduced carbon output for your process?

At Vistech Cooling Systems, we specialise in auditing, upgrading and maintaining all cooling system types – whether you’re ready to replace an ageing induced-draft unit, retrofit noise-reduction measures on a forced-draft installation or explore advanced crossflow pack arrangements. Our expert engineers will assess your site, model performance gains and design a solution that meets both your production demands and your sustainability goals.

Ready to find out how much you could save? Contact us today for a no-obligation site survey or performance review:

- Call us on 01403 892 622

- Email info@vistechcooling.co.uk

- Visit https://www.vistechcooling.co.uk/about-us/contact-us/

Let’s make sure your cooling tower is working as hard as you are—efficiently, reliably and sustainably.