Now we’ve established the three main cooling tower designs, there is now a further choice to make. When it comes to replacing towers, this is where it can get interesting…bear with me.

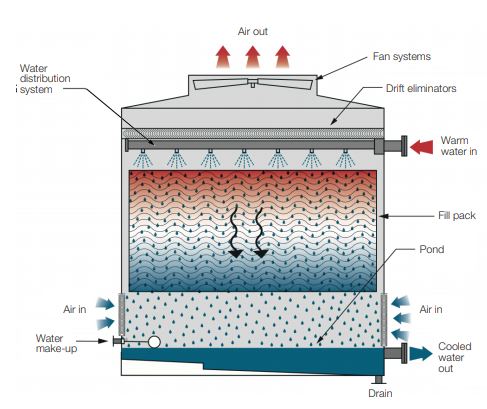

What Is an Open Circuit Cooling Tower?

An open circuit tower is where the process cooling water is in direct contact with the heat transfer material, fill packing. This is highly efficient, as we are using the full potential of evaporative cooling to remove heat from the process water directly. The process water will be prone to fouling if water treatment isn’t kept in check, but a robust water treatment regime may assist.

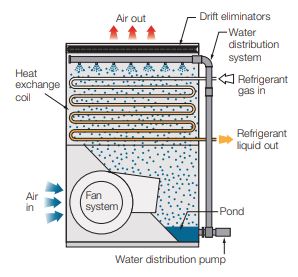

What Is a Closed-Circuit Cooling Tower?

In a closed-circuit tower (which is not an evaporative condenser*), the process fluid (sometimes just water, hopefully a water/glycol mix) is separated from the cooling water by way of a heat exchange coil. This coil circulates the process fluid and is cooled indirectly: the surrounding spray water, which is evaporatively cooled within the tower, transfers heat to the atmosphere, thereby reducing the temperature of the fluid inside the coil through sensible heat exchange. This is a less efficient means of cooling and hence for the same duty the tower/s will be in the region of double the size of the open circuit equivalent. However, they do separate the process fluid, reducing contamination and fouling in the system.

From visiting hundreds of sites with closed-circuit towers, there are a high majority of these which appear to have no justification for separating the cooling water from the process water. They were heavily promoted back in the 90’s as a way to reduce water consumption as they could be used in dry mode as a dry air cooler during cooler months of the year and only use the spray system during the summer.

“Closed Circuit towers are the sofa beds of the cooling tower world…neither a plush sofa nor a comfortable bed”

Misuse of Closed Circuit Towers in UK Industry

The problem with them is that they are the most inefficient imitation of a dry air cooler (DAC) and demand high levels of energy in this mode and when in wet mode, consume more water through evaporation, blowdown and drift than an open circuit equivalent, due to higher make up levels caused through the more inefficient heat transfer process. Instability in water chemistry due to the small recirculating circuit means that water treatment costs can be far higher in these systems.

As an aside, earlier this year I visited a cement factory that had 14 closed-circuit towers on-site cooling kiln jackets. The coils within the towers were caked in cement and were extensively corroded by the alkaline dusty atmosphere. These towers never needed to be closed circuit and financially, it is not viable to replace the coils within the towers. Installing a new coil is similar to the price of a new tower. When the coil dies, the tower dies with it. With plastic packing material, this could have been regularly replaced as a consumable, prolonging the life of the tower.

Corroding Coil

“But,” I hear you ask, “is there a way of protecting the process water but keeping the benefits of the open circuit tower?”

Yes there is…you can have your cake and eat it or your sofa and your bed if you will…(don’t eat the cake in the bed)…by way of introducing a plate heat exchanger with an open circuit tower to create a closed process loop. The tower is sized efficiently, and the plate heat exchanger can be easily cleaned, or plates replaced cost effectively to maintain system optimisation. This is an effective way of retaining a closed loop system but gaining system efficiencies when the time comes for replacement and there are modular options on the market for skid-mounted systems that include the cooling tower, circulating spray pumps and heat exchanger ready for installing as a direct replacement for a closed-circuit tower.

Ready to Upgrade Your Cooling System?

At Vistech Cooling Systems, we help clients rethink legacy systems to reduce operational costs, improve efficiency, and extend asset life. If you’re replacing a tower, don’t just replicate but re-evaluate.

📞 Get in touch today to discuss whether your next system should be open circuit, closed circuit or a smarter solution altogether.