In industrial settings, sound is more than a nuisance! It’s a regulatory, operational, public and employee welfare concern. For plant engineers, HSE leads, and facilities teams managing cooling towers and adiabatic systems, sound levels can quickly become a hidden liability.

When designing or replacing a cooling tower system, most engineering teams focus on thermal duty, flow rates, and footprint. But sound is a key and critical factor both in terms of power output and perceived pressure for the compliance of your new system.

Whether you’re planning for planning (literally), safeguarding site operatives, or future-proofing against rising compliance standards, understanding how acoustics should influence your cooling tower design is no longer optional.

In this article, we explain what really matters from fan type to sound attenuation, site placement, and system layout so you, the client, can avoid costly oversights and deliver a quieter, compliant installation.

Understanding Sound Power vs Sound Pressure: Why It Matters for Your Site

Let’s start with the basics, because this is where many misunderstandings begin:

- Sound Power is the actual acoustic energy generated by a source think of it like the volume level on a speaker.

- Sound Pressure is what people actually hear – and it’s affected by distance, surfaces, and environmental factors.

The sound power of a cooling fan remains constant regardless of location. But sound pressure can double, quadruple, or more depending on:

- Proximity to walls or corners

- Mounting height above the ground

- Open field vs enclosed plant room

A simple way to understand this? Try playing music from your phone.

Lay it flat on the floor and listen. Now place the speaker end into a mug or cup.

Which sounds louder?

Its the mug scenario and by quite the margin… The sound waves bounce off the hard curved surface and amplify the pressure you hear. It’s the same principle behind reflected noise in cooling tower design.

(Use this next time you forget your prized portable speaker!)

Understanding how these dynamics play a role in acousitic compliance early prevents non-compliance with local authority limits and protects your design from later restrictions.

Fan Type and Configuration – The First Decibel Decision

The biggest contributor to sound power in a cooling system is the fan assembly and not just the fan itself, but its motor, drive, blades, and mounting structure.

Axial vs Centrifugal

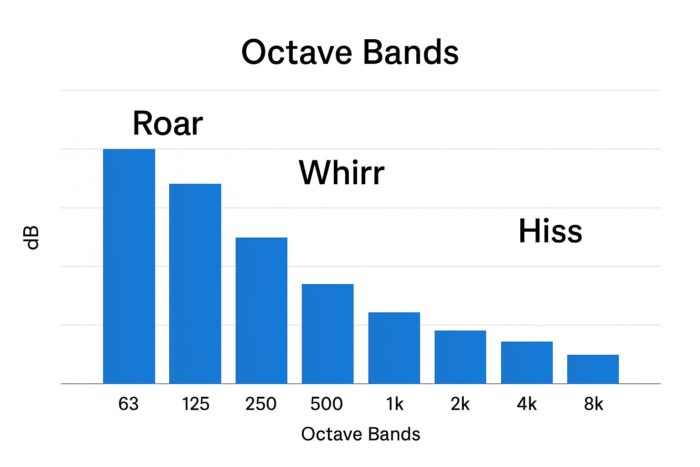

- Centrifugal fans, especially in enclosed setups, produce more “whirr” in the mid-range frequencies (500–2000 Hz).

- Axial fans (used in most open-circuit towers and adiabatic coolers) typically produce higher low-frequency “roar” (125–500 Hz).

🌀 Blade Geometry

- Forward-curved = quieter at lower RPMs, but noisier at higher loads

- Backward-curved = more efficient at duty point, but can introduce high-frequency “hiss” (2k–8k Hz)

⚙️ Drive System

- Belt drives are cost-effective but noisier long-term as belts degrade.

- Direct drive or EC motor systems offer quieter, more controllable operation.

✅ Vistech Tip:

Specify fan types not just by airflow and efficiency but by target noise compliance levels paying special attention to the difference between sound pressure and power.

Attenuation and Enclosure: Don’t Leave It Until the End

Design teams often treat acoustic attenuation as a bolt-on fix. That’s risky.

Here’s what we advise:

🔇 Intake and Discharge Silencers

- Add attenuation at intake (air inlet) and/or discharge (air outlet) points

- Especially important for units near offices, walkways, or site boundaries

🧱 Structural Enclosures

- Full acoustic cladding can be effective, but must be engineered with airflow pressure drop in mind

- Reflective surfaces inside enclosures can actually worsen dB(A) unless properly dampened

📏 Placement Matters

- Place towers away from corners or walls where possible

- Mount higher where reflections are minimised, or ensure ground-based barriers are in place

Site Constraints, Planning Limits, and Compliance Risks

We’ve seen countless UK manufacturers often forget that sound levels at site boundaries are planning-sensitive and especially with residential neighbours, business parks, or local authority regulations.

📜 Planning Conditions

- Councils may impose strict dB(A) limits at 1m outside boundary fences

- These limits often vary by time of day (e.g. 55 dB(A) daytime, 45 dB(A) night)

📉 Octave Band Analysis

- For high-risk sites (distilleries, urban, pharmaceutical), we use third octave band analysis at 125 Hz–8k Hz band breakdowns to identify trouble areas

- What it is: Instead of lumping noise into broad octave bands (e.g. 125 Hz, 250 Hz), third-octave data splits each into three narrower ranges.

Why it matters:

More detailed fingerprint of the noise.

Regulators are especially concerned about tonal noise, since it’s perceived as more annoying, even if overall dB(A) is compliant.

For cooling towers:

Fan blade pass frequency and gearbox harmonics often show up clearly in third-octave analysis.

If these peaks exceed background noise by >5 dB, local authorities may demand mitigation.

- What it is: Instead of lumping noise into broad octave bands (e.g. 125 Hz, 250 Hz), third-octave data splits each into three narrower ranges.

💼 Detailed Documentation for Tender/Planning

- We help clients include SPL tables, and third-octave data in design packs as it speeds approvals and removes ambiguity…. but what does this all mean:

- SPL Tables (Sound Pressure Level Tables)

What they are: A tabulated set of measured or predicted sound pressure levels (in dB) at various octave or third-octave frequency bands.

Why they matter:

Sound isn’t just “one number” as a cooling tower might have low-frequency rumble (125 Hz) that carries further and penetrates walls, while another may have mid-frequency “whirr” (1–2 kHz) that people find annoying nearby.

By showing SPL broken down by band, you give consultants the data they need to model compliance against local criteria.

- SPL Tables (Sound Pressure Level Tables)

Our Perspective: Acoustic Thinking from Day One

At Vistech, we take acoustic compliance beyond a simple noise survey, providing the level of detail councils and acoustic consultants require reducing planning risk and avoiding costly rework later. We design cooling systems with sound in mind from the first conversation. Whether it’s helping a Scottish distillery stay compliant with new planning noise limits, or guiding an aerospace client through noise compliance for their process cooling, we consider acoustic performance from the start.

Because once that tower is installed…… your options narrow and likely costs rise!

Looking to Design a Cooling System That Won’t Come Back to Haunt You?

If you’re planning a new cooling tower installation, adiabatic system, or chiller upgrade, and sound is, or you now have realised it should be, on your radar, we can help.

Speak to our engineering team about:

- Sound pressure/Power reports

- Fan and attenuation selection

- Site layout to manage acoustic reflections

- Planning submission support