Compact open cooling towers pre-assembled at factory

EWK-A SMART

Closed circuit adiabatic water coolers, Legionella free.

-

Reduces energy consumption using the “smart towers” scheduling capabilities to only run the tower during set periods of the day. As a result, less energy is used and lower noise levels are observed during off peak hours when there is less demand for heat rejection.

-

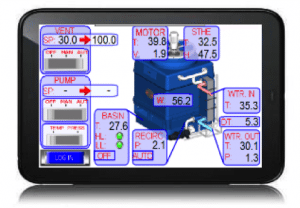

Full remote access of the “Smart Cooling Tower” is possible anywhere in the world using a PC or smart device via a Modbus TCP/IP (two way) communication system. This system allows full monitoring of the towers functionality and ensures that any alarms are received and actioned by key personnel on or off site.

-

Outlet temperatures are constantly monitored using built in temperature probes. The control panel uses the temperatures obtained to optimise the tower functionality and control using the VSD.

-

Regulation of the primary circuit pump according to the process parameters.

-

A central monitoring unit enables the autonomous management of the tower, based on the set parameters and the information gathered from the various probes installed. The main component is a PLC that integrates algorithms, PID to optimise the power consumption of the fan motors and circulating pumps motors, according to the set-point values introduced. (Circulating pumps are only available on closed-circuit tower range).

The control panel comes as standard with a 4.3” touch screen, allowing full operational control of the “Smart Cooling Tower”. As an optional extra the screen size can be increased to 7” & 10”.

-

Monitors the outside conditions around the cooling tower, making it possible to remotely appraise the performance of the ”Smart Cooling Tower” based on the design criteria.

-

PRIMARY: Allows accurate monitoring of the process water flow rate.

SECONDARY: Detects the dirt on the circuit and recommends maintenance tasks in filter and heat exchanger.

-

VSDs adjust the rotation speed of the fan motors according to the parameters set on the control panel. This device integrates the control software with PID algorithms, which optimise energy consumption and recommend preventive maintenance.

The VSD is able to monitor the following useful information:

Motor rotation speed.

Current through the motor coils.

Voltage.

Power consumption.

EWK-A SMART Display

- Inlet and Outlet Temperature Probes

- Primary Circuit Pump Control

- Oil / Motor Temperature Probe

- Water Level Control

-

Inlet and outlet temperatures are constantly monitored using built in temperature probes. The control panel uses the temperatures obtained to optimise the tower functionality and control using the VSD.

-

Regulation of the primary circuit pump according to the process parameters.

-

Measures the temperature of the gearbox oil and motor coil. If a set temperature is exceeded occurs the probe sends an alarm signal or stops the motor, preventing possible damage to the motor/gearbox and consequently to the equipment in general.

-

Sends high and low level alarms to the control panel should the water level fall out of the set parameters, preventing the sump from draining down or overflowing. When the level is normal the equipment works with no restriction.

Smart Cooling Towers