When industrial cooling is needed on a manufacturing site, a common question arises: what’s cheaper to run – a cooling tower/adiabatic cooler or a chiller? This is a crucial consideration for plant engineers and project managers under pressure to control costs and energy use. With UK industrial electricity prices about 50% higher than those in France or Germany, choosing the right cooling method can significantly impact operating expenses. In this article, we’ll break down how cooling towers and chillers differ in cost structure, energy consumption, water use and maintenance needs as well as explain which option (or combination) can be most economical for process cooling in a manufacturing environment.

Cooling Towers vs Chillers – Key Differences in Cost and Efficiency

Cooling towers and chillers both remove heat from process water, but they do so in fundamentally different ways that affect their costs. A cooling tower relies on evaporative cooling: it sprays water and uses a fan to evaporate a small portion, carrying away heat. A chiller, on the other hand, uses a refrigeration cycle (compressors and refrigerant) to chill water, then rejects heat either to air (air-cooled chiller) or via a cooling tower (water-cooled chiller. These differences lead to distinct cost factors:

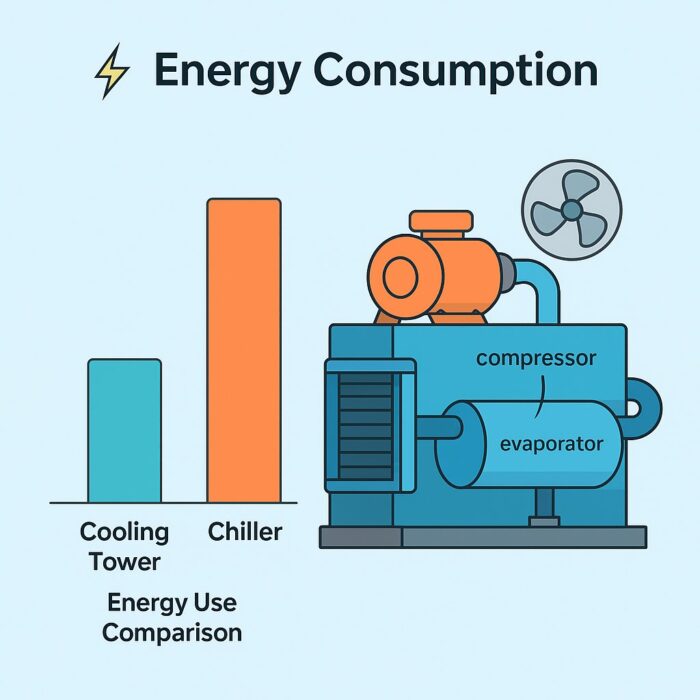

Energy Consumption ⚡💨:

Cooling towers use relatively little electricity when compared with chillers. Evaporative cooling is the most efficient form of heat rejection. The phase change of water removes heat with minimal mechanical energy and in fact evaporative cooling can be potentially 1000 times more effective at heat removal than using air cooling alone such as the method used in an air cooler. This means a cooling tower can reject large heat loads with a fraction of the power a chiller would require. By contrast, chillers use power-hungry compressors which in turn provide precise cooling but at a higher energy cost (Liao et al. 2019). In practical terms, a cooling tower’s lower electrical use translates to lower running costs on your energy bills which is a major advantage given high and rising electricity prices.

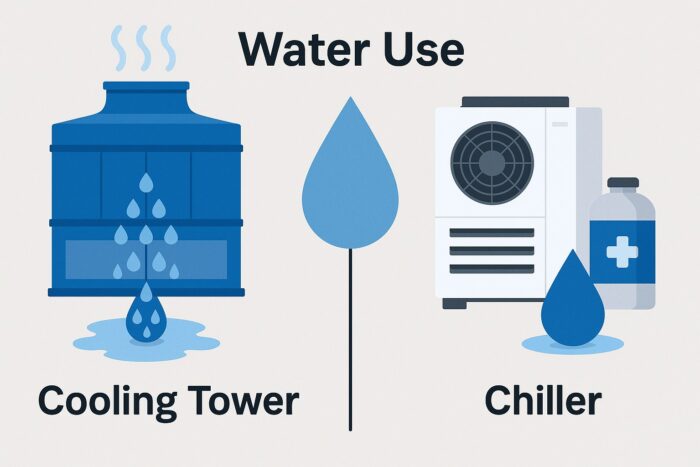

Water Use and Treatment 💧🧪:

The flip side to an evaporative cooling tower’s efficiency is water consumption. Cooling towers continuously evaporate water by design, so considerations are made for this evaporation loss as well as management of blowdown (to remove mineral solids build up from the system). Water isn’t free and is becoming more heavily regulated as well as scarce in many regions of the UK. This addition to operating costs of an organisation is sometimes considerable and therefore when directly comparing cooling towers and chillers it is an important consideration. While these can be significant, electricity savings from a tower almost always outweigh water costs….

For example, an open cooling tower system requires a consistent water make up and chemical water treatment to prevent scale, corrosion, and biological growth (like algae or bacteria). Chillers (especially air-cooled types) are able to close this loop ensuring water usage at its lowest possible output. However, modern solutions like adiabatic coolers can bridge this gap and are able to cut water usage in a system. In one of our recent distillery projects, we employed adiabatic coolers which cut water use by 90% when compared to a conventional cooling tower, while still leveraging identical evaporative cooling effects. Please give this article a read on adiabatics a read! The important takeaway is that water costs and the treatment program associated with a cooling tower must be weighed against the huge electricity costs of a chiller. Often, these electricity savings can outweigh the additional water expenses, but every facility’s calculus and bias will differ.

Maintenance and Compliance 🛠️📋:

Both systems need maintenance, but the tasks differ. Cooling towers are essentially open water systems, meaning you’ll have to manage water quality and inspect components like fill media, drift eliminators, and fans. Legionella control is a critical factor which comes with a whole host of real-world headaches…. cooling towers must be monitored and treated to prevent bacteria, as required by health and safety regulations (e.g. UK’s ACOP L8). Although, with proper water treatment and regular cleaning, the Legionella risk can be effectively managed, but this of course comes with a recurring maintenance cost. Tower components also need periodic refurbishment (replacing fill packing, geared motors, etc.) to keep efficiency up. Of course, chillers have a different maintenance profile such as servicing compressors, checking refrigerant levels for leaks, cleaning condensers/heat exchangers, etc. Chiller maintenance can be technical and parts like compressors are incredibly expensive which is another cost worthy of note. In summary, cooling towers can have higher routine maintenance overhead (water treatment, cleaning) whereas chillers incur higher energy costs and typically higher upfront capital cost. Any cost comparison should include these lifecycle factors, not just water and energy bills you might catch a glance at once in a while!

What Is Wet-Bulb Temperature and Why It Matters for Cooling Towers?

Wet-bulb temperature is the lowest temperature that can be achieved by the adiabatic evaporation of water into the air until the air becomes fully saturated (100% relative humidity). Heat is taken from the surrounding air during this evaporation, resulting in cooling. Think of how stepping out of a shower or pool leaves you feeling cool – this is the same physical principle at work.

In practical terms, a cooling tower can only cool water to within about 3 °C of the ambient wet-bulb; This is referred to as the approach temperature. In the UK, summer wet-bulb temperatures typically range from 17 °C to 21 °C, meaning a tower alone can usually supply process water in the region of 20 °C to 24 °C range at best.

Chillers, however, are not bound by wet-bulb limitations as they use a refrigeration cycle for cooling. This means they can consistently supply water at 5 °C to 20 °C (or even lower) regardless of humidity or ambient conditions.

Essentially, if your process can run comfortably at or near wet-bulb-plus-3 °C, a cooling tower will almost always be more energy-efficient. If it needs colder water year-round, a chiller (or hybrid system) is the only viable option.

Why Cooling Towers Rely on Wet-Bulb Temperature

Cooling towers cool process water by evaporating a portion of it; the heat required for this evaporation is drawn from the water itself—thus cooling it down to a temperature that approaches the ambient wet‑bulb.

- The closer the cold-water outlet temperature is to the wet‑bulb, the larger the required heat exchange surface area (fill) of the tower.

- If a tower for example, handles a 500 kW duty with a 4 °C approach (difference between cold-water temperature and wet‑bulb), it must be physically larger than one designed with a 7 °C approach.

Pros & Cons of Chillers/Cooling Towers at a Glance

| Factor | Cooling Towers | Chillers |

| Energy Use | Very low vs. chillers; uses evaporative cooling to remove heat efficiently. | High; compressors are power-intensive. |

| Water Use | High due to evaporation and blowdown. | Low (air-cooled) or moderate (water-cooled). |

| Maintenance | Regular cleaning, water treatment, and Legionella control required. | Technical servicing of compressors/refrigerant; expensive repairs possible. |

| Capital Cost | Lower than large chillers for equivalent duty. | Higher, especially for low-temperature duties. |

| Temperature Capability | Limited to ~3 °C above ambient wet-bulb. | Can cool to well below wet-bulb (e.g., 5–20 °C). |

| Best Use Case | Large, constant heat loads with moderate temperature requirements. | Processes needing very low or precise temperatures year-round. |

Operating Cost Comparison – When Each Option Makes Sense

For most process cooling needs in the manufacturing sector, the cheapest option long-term is the one that best exploits ambient conditions while meeting the required temperatures. Cooling towers excel at low-cost heat rejection when your process can work with water temperatures near the ambient wet-bulb temperature (typically between 17–21 °C minimum in the UK). They are able to take advantage of “free cooling” from the atmosphere effectively utilising evaporation with minimal low maintenance mechanical elements. Of course, in cooler weather or at night, a cooling tower alone may keep your water cool enough for the processes requirements, allowing you to avoid running a chiller at all; saving significant amounts in water and energy. In fact, a properly designed system can often use a cooling tower to provide the critical cold water temperature for a process for much of the year, so a trim chiller would only need to be run during the hottest peak conditions of the year. The energy savings can be enormous according to a U.S. Department of Energy study, the use of a cooling tower and heat-exchanger circuit to chill water directly (bypassing the chiller) can cut the cost of producing chilled water by up to 70%. This is why many industrial plants use water-cooled chillers with cooling towers in order to dramatically improve the chiller’s efficiency by rejecting heat at a lower temperature, and it enables evaporative cooling to handle the bulk of the heat rejection duty when ambient conditions allow.

However, chillers come into their own when lower temperatures are needed or when ambient conditions are unfavourable. Chillers can also be used as standalone solutions, for instance, in smaller systems or where heat loads are moderate, a chiller’s simplicity might make it the more cost-effective choice overall through avoiding the fixed costs of associated with water treatment programs and tower installations. It’s often in large-scale manufacturing or heavy industry that cooling towers show the greatest cost advantage, precisely because the heat loads are high and continuous, which brings us to the key point of the more heat you have to dump, the more it pays to do it with a cooling tower! (the most energy-efficient method). Using chilled water at 5 °C to cool a process can cost an order of magnitude more than using 30 °C cooling water from a tower, in terms of energy a client’s main concern should be what is the desired cold water temperature they or specifically YOU require!

The Role of Trim Chillers (Hybrid Systems)

In practice a hybrid approach to cooling on site can save clients huge amounts of money. Rather than an all-or-nothing decision, the most cost-effective solution can be pairing a cooling tower (or adiabatic cooler) with a trim chiller. A trim chiller is a smaller chiller unit that only kicks in when the cooling tower alone can’t meet the critical cold water temperature setpoint on hotter days or during peak loads. Most of the time, the tower provides sufficiently cool water; the trim chiller “tops up” the cooling only when required, ensuring process temperatures stay in range. The benefit of this strategy is significant: you avoid buying and running a huge chiller for the worst-case scenario that only occurs a few days per year. Instead, you run a much smaller chiller intermittently, and the cooling tower does the heavy lifting by the most efficient means. As our technical director described it, the trim chiller removes additional heat from the system only when required as it’s the first-off, last-on unit. By downsizing the chiller and minimising its run hours, sites have seen chiller energy usage and runtime cut by 50% or more in comparison to relying on a chiller 24/7.

In our experience at Vistech, this hybrid approach delivers the best of both worlds: the low operating cost of evaporative cooling with the precise control of mechanical refrigeration when needed. It’s especially popular in manufacturing sectors where cooling demands fluctuate with seasons or batch processes. For example, a plastics plant might use cooling tower water for most of the year and only engage a trim chiller during the hottest summer afternoons or for particularly heat-sensitive production runs. The result is a dramatic reduction in annual cooling costs without sacrificing reliability or product quality.

Our Perspective: Finding the Cheapest Solution for Your Needs

Having designed and installed industrial cooling systems across the UK, Vistech has learned that the question “cooling tower or chiller – which is cheaper?” doesn’t always have a one-size-fits-all answer. Our approach is to evaluate your specific process requirements, site conditions, and long-term costs. In many cases, we’ve found that a well-engineered cooling tower system wins on running cost especially for large manufacturing processes but it’s crucial to account for water availability and maintenance capabilities. We often recommend combining technologies: for instance, using an adiabatic or evaporative cooler for base-load cooling and a trim chiller for peak trimming.

This kind of solution recently helped one of our clients in the distillery market slash their chiller electricity usage while meeting strict temperature requirements, by letting the cooling towers reject the bulk of the heat load and only trimming the cold water temperature if required with the chiller on the hottest days. Ultimately, “cheaper” in cooling comes down to total cost of ownership which includes energy, water, maintenance, and reliability. We pride ourselves on honestly assessing these factors. Sometimes that means telling a client their existing cooling tower can be refurbished and paired with a small chiller for huge savings; other times it means recommending a new chiller with heat recovery for efficiency. Our goal is always to deliver a solution that minimises ongoing costs while keeping your process safely cooled.

If you’re facing a cooling challenge or trying to reduce your plant’s operating costs, speak to our engineering team. We’re happy to share our real-world experience and consultancy expertise on your cooling setup – whether it be a tower, chiller or adiabatic solution that best fits your process and budget.

https://www.theguardian.com/business/2025/mar/15/uk-steel-industry-energy-prices-trump-trade-war

Liao, J., Xie, X., Nemer, H., Claridge, D.E. and Culp, C.H., 2019. A simplified methodology to optimize the cooling tower approach temperature control schedule in a cooling system. Energy conversion and management, 199, p.111950.

Pontes, R.D.F.F., 2024. Cooling Towers and Chilled Water Systems: Design, Operation, and Economic Analysis. Elsevier.