Why Cooling Towers Consume So Much Water

Cooling towers are among the most water-intensive assets on industrial sites. Yet with the right design, monitoring, and control strategy, make-up demand can be cut by 30–70 % without compromising cooling duty or compliance. This guide explains where water losses occur, how to quantify them, and the retrofit and design interventions that deliver the greatest return.

The True Cost of Cooling Water

- First-order estimate: ~1.8 L evaporated per kWh heat rejected.

- For evaporative systems, latent heat of vaporisation of water ≈ 2,430 kJ/kg (at ~30 °C).

- That means:

- To reject 1 kWh of heat (3,600 kJ), about 3,600kJ÷2,430kJ/kg≈1.48kg≈1.48L of water must evaporate.

- Typical water cost per tower through blowdown and water treatment can be upwards of £10k

- Many plants underestimate the total cost (hidden treatment, heating, and discharge costs).

- Distinguish unavoidable evaporation from avoidable drift and bleed losses.

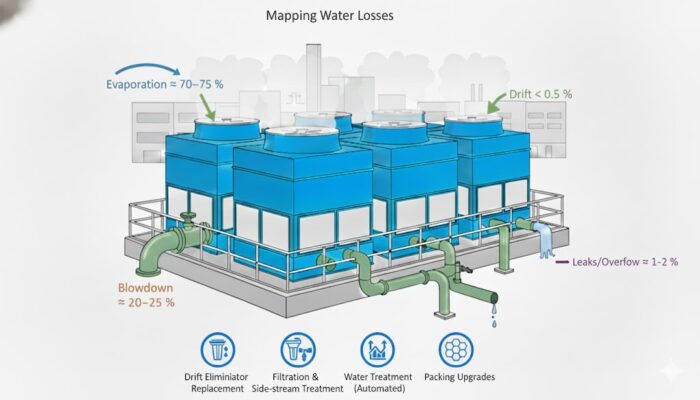

Cooling Tower Water Loss Breakdown

Breakdown of a typical open-circuit tower’s make-up water use:

- Evaporation ≈ 70–75 %

- Blowdown ≈ 20–25 %

- Drift < 0.5 % (Dependent on Cooling Tower Efficiency)

- Leaks/overflow ≈ 1–2 %

Visualise where interventions act (drift eliminators, conductivity control, bleed recovery).

Retrofit Options to Reduce Water Consumption (30–70% Reduction)

Filtration and side-stream treatment:

Reducing suspended solids in a cooling tower will reduce the frequency of blowdowns for the system.

Drift eliminator replacement:

Modern efficiency drift eliminator units cut these key losses to <0.005 % of the circulation rate.

Water Treatment:

By upgrading to automated water treatment and bleed control, you can maintain higher cycles of concentration (3–6×) without over-bleeding.

Packing upgrades:

Cleanable anti-legionella high efficiency modular packing improves heat transfer → lower approach temperature → less evaporation for the same duty.

Design-Stage Choices That Dictate Long-Term Water Use

- System Type:

- Open-circuit: lowest energy, highest water use.

- Closed-circuit/Condenser: lower drift and blowdown, but higher fan/pump kW and cooling efficiency.

- Adiabatic coolers: 90 % less water, but higher dry-mode energy use.

- Approach temperature design: If your tower is designed to have a tighter approach temperature to the ambient wet bulb this results in → A larger tower → More evaporation → More water loss .

- Automation & controls: integrate conductivity, humidity, and basin level sensors from day one.

SMART Monitoring & Predictive Maintenance

- SMART Tower control with water make-up monitoring, conductivity sensors, and remote data logging.

- Trend analysis and SMART dashboards: m³ per MWh rejected.

- Mechanical maintenance contracts ensure clients are warned early. This results in benefits such as detecting leaks, or scaling before costs escalate.

Vistech Perspective

Vistech advocates whole-system design rather than piecemeal fixes. The goal is predictable cooling with minimal water and compliance burden. For many UK industrial sites, the next real saving will come not from “cheap water” but from accurate measurement and controlled losses.

Practical Checklist (10 Points)

- Meter make-up and blowdown separately.

- Log water use per MWh rejected.

- Maintain accurate conductivity control.

- Inspect drift eliminators annually.

- Replace fouled or brittle fill.

- Check bleed valves for leakage.

- Audit water chemistry vs cycles of concentration.

- Validate all changes under ACOP L8 / HSG 274.

Suggested Calls-to-Action

- Book a technical survey – verify water and energy balance.

- Download comparison guide – adiabatic vs evaporative vs hybrid.

- Request retrofit quote – drift eliminator, bleed control, or pack replacement.

- Speak to Vistech’s engineers – model site-specific savings.