Why Crossflow Packing Needs a Rethink

Anyone who has tried to slide a neatly ironed shirt back into an overfilled wardrobe knows the outcome. No matter how carefully you work, the shirt comes out worse than it went in. This is nearly identical to what happens when maintenance teams try to re-hang individual heat transfer plates inside a crossflow cooling tower.

Crossflow towers are often marketed as easy to clean. In practice, that promise rarely matches the reality on site. This is not a criticism of crossflow towers as a technology. They have strong air intake performance and good general access. The problem is the hanging packing design that sits at the heart of most models.

What the OEMs Say

On paper, the concept looks ideal. Major OEMs present a confident message.

SPX and Marley describe MX75 hanging fill as delivering long service life with minimal maintenance. They highlight wide sheet spacing, reduced clogging, and maximum water surface exposure.

BAC promotes its Series 3000 as using a continuous hanging sheet fill that supports smooth top-to-bottom water flow while offering easy cleaning and easy maintenance.

EVAPCO states that its crossflow fill provides high thermal performance with minimal maintenance needs.

All three focus on surface area, smooth water flow, longevity, and low maintenance.

What none of them explain is how operators are expected to keep hanging fill clean enough to deliver this long service life in real conditions. No major OEM offers a clear, practical process for removing hanging sheets, lifting them without damage, accessing the sump underneath, dealing with sagging or deformation, or reinstalling sheets that have become brittle or weighted down with fouling. They also do not address how uneven airflow and dry spotting can develop over time.

As towers age, the gap between the claims and the day-to-day reality becomes more obvious.

The Real-World Experience

Foam and chemical cleans are often used as substitutes for proper access, but foam behaves like water in operation. It follows the easiest path. The result is that fouled areas stay fouled. Biological loading rises. Legionella risk increases. And because hanging fill often sags into the sump, that sump can no longer be cleaned properly.

Crossflow towers could be easy to maintain. The hanging fill design prevents that. Operators end up choosing between fighting with the fill every time or accepting that it will never be fully clean. Most sites choose the latter, often by necessity rather than preference.

OEM Guarantees and How They Hold Up

A natural question follows. If non-OEM packing is installed, does that void the OEM performance guarantee?

Potentially yes, but an uncomfortable truth sits behind this point. On many installations, the guarantee has already fallen out of scope long before anyone thinks about replacing the packing.

OEM guarantees depend on ideal conditions. SPX, for example, states that performance depends on correct water management, perfect mechanical condition, perfect installation, full adherence to OEM maintenance instructions, suitable water quality, and the absence of fouling. BAC makes similar statements, noting that performance relies on correct selection, correct installation, proper water treatment, and ongoing care.

Very few real sites meet these criteria. Fouling starts immediately. Water chemistry shifts. Hanging fill sags. Air distribution changes. Drift eliminators degrade. Spray patterns move. Sumps accumulate debris that cannot be removed because the fill hangs into the working space.

Most sites also lack complete maintenance records, original certified thermal test data, full water treatment audit trails, aligned environmental conditions, and witnessed performance checks.

The result is that the performance guarantee often becomes a theoretical document, not an operational safeguard.

A Practical Alternative

The most effective solution is straightforward.

Install modular block packing on a raised support platform.

This approach allows the packing to be removed in solid sections, stops sagging into the sump, lifts the media above the waterline for proper sump cleaning, spreads load evenly, and makes deep cleaning practical. It supports consistent thermal performance throughout the life of the pack and reduces fouling by eliminating dead zones.

Modular block packing does more than improve heat transfer. It restores maintainability to the cooling tower.

Case Study: UK Meat Processing Facility

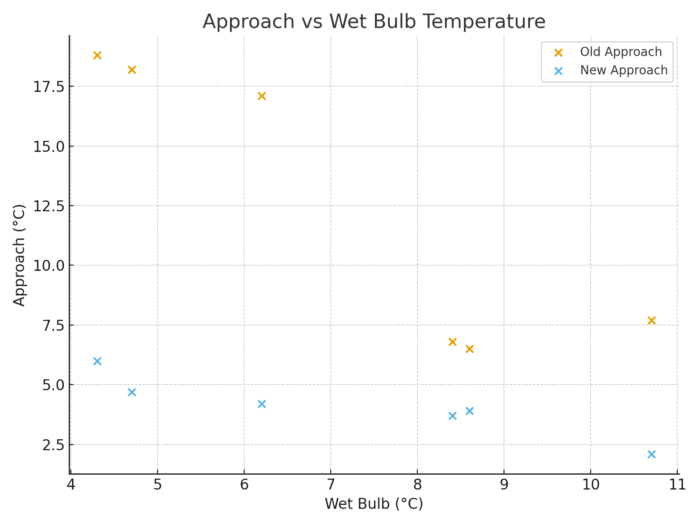

A UK meat processing facility (name withheld for confidentiality) replaced its OEM hanging fill with Vistech modular block packing. The site recorded performance under matched operating conditions. That means the same wet bulb temperature, the same thermal load, and data captured during production.

Key Results

Average approach with OEM fill: about 12.5 C

Average approach with Vistech block pack: about 4.1 C

Improvement: about 8.4 C

This improvement occurred during a period where the average wet bulb temperature was 5 C higher than during the OEM baseline. In other words, the tower performed better under worse ambient conditions.

Chart showing Approach versus wet bulb and a histogram of the improvement. The uplift is far beyond anything that could be explained by sensor drift or natural stratification.

Energy Impact

Site benefits were significant enough to note by the client. Ammonia compressor energy use typically falls by 2 to 3 percent for every 1 C reduction in condensing temperature. With a reduction of about 8.4 C, this site achieved an estimated 17 to 25 percent cut in compressor energy consumption.

The Link Back to Maintenance

The message behind this data is clear. The performance gain is not a mystery. It is maintenance. It is what happens when an unmaintainable system is replaced with one that can be cleaned properly.

By removing sagging sheets, inaccessible sump debris, uneven airflow, and the challenges of reinstalling distorted plates, and replacing all of this with a rigid, removable, maintainable structure, the tower finally performs as designed.

This is the part that OEM literature does not address.

Better maintenance leads to better performance. Better performance leads to lower energy use and longer asset life.

For crossflow towers, modular block packing is the only system that makes this truly achievable.

Next Steps For Your Crossflow Cooling Tower

If you want a realistic assessment of what your tower can deliver, not the theoretical number on an old OEM datasheet, speak to our engineering team.

We’ll look at your condition data, photographs and operating profile and outline practical options, costs and associated downtime.