When UK temperatures dip below zero, cooling systems face one of their biggest hidden risks: freezing. It’s not just the pipework that suffers; pumps, buffer vessels, closed-circuit coils, and even filtration systems can be damaged in a single cold snap.

Every year, we see cases ranging from minor insulation failures to catastrophic coil ruptures. It’s a common scenario coil’s of adiabatics or closed circuit towers rupturing, and we see this evidenced across the UK, including at one Midlands automotive site, which experienced a single frozen buffer vessel that cost more to replace than the tower itself. For another London-based facilities management company, their pump seized after a small ice formation split the casing, and these repair bills ran into tens of thousands.

Understanding which parts of your system are most at risk and why is the first step to protecting your cooling system through the winter.

| Component | Freeze Risk | Typical Consequence | Best Protection |

|---|---|---|---|

| Pipework | Medium (exposed, uninsulated runs) | Burst sections, leaks, downtime | Lagging, trace heating, circulation, and drain-down for seasonal usage |

| Pumps | High (water left stagnant inside casings) | Cracked casings, seized bearings, full failure | Lagging, trace heating, circulation, and drain-down for seasonal lines |

| Buffer Vessels/Tanks | High (large stagnant water volumes) | Bulging, cracked welds, total vessel failure | Drain when idle, maintain low-flow circulation, and heated enclosures where exposed |

| Closed-Circuit Coils | Very High (stagnant process water) | Coil rupture, often uneconomical to repair | Tank heaters, glycol dosing, and full drain if offline |

| Filtration/Strainers | High (small stagnant volumes) | Split housings, contamination on restart | Insulate, trace heating jackets, and drain when isolated |

| Install FPUs, glycol blends in spray lines, and insulate exposed runs | High (pipes & valves freeze quickly) | Split headers, pump and valve damage | Insulate, trace heating jackets, and drain when idle |

Why Cooling Systems Freeze

Water expands by around 9% when it freezes. In sealed components like coils or pumps, this expansion has nowhere to go, creating pressure strong enough to rupture their metal housings. Once that happens, repairs are rarely economical: a split copper coil or cast pump body usually means full replacement…. not something any client wants to hear!

These problems are magnified when systems are idle or poorly designed to combat the cold snaps of the UK. In the UK, the risk isn’t just confined to Scotland or the North; exposed sites in the Midlands and South East can be hit just as hard, especially if they’re open to wind chill, have poor drainage or are located in industrial estates with little shelter.

Components Most at Risk

Pumps

Pump casings often fail first when water is left in a stationary pump, which can freeze, cracking the casing and seizing bearings and unfortunately for most, the first sign of damage is typically when a pump refuses to start in the spring…. when it is too late!

Buffer Vessels and Tanks

Large water volumes in tanks can freeze solid overnight. The resulting pressure can bulge or split weld seams, leading to full vessel failure. Replacement costs and downtime from cranage and fabrication often exceed the 10’s of thousands.

Closed-Circuit Coils

The most expensive failures occur in closed-circuit towers or adiabatic coolers as a burst coil usually means replacing the entire coil section often 50% or more of tower value. Prevention relies on continuous circulation, correctly dosed glycol protection or an FPU unit.

Filtration and Strainers

Side-stream filters, dosing pots, and strainers freeze quickly due to small stagnant volumes. Split housings normally require complete replacement.

Different Fluids: Water vs Glycol

| Fluid | Advantages | Drawbacks | Typical Application |

|---|---|---|---|

| Water only | Highest heat-transfer efficiency | Freezes at 0 °C | Open-circuit towers where basins can be drained or heated |

| Glycol blends | Depresses freezing point (–10 °C to –25 °C depending on concentration) | Reduces thermal efficiency, requires monitoring | Closed or adiabatic circuits |

Many UK manufacturing sites opt for hybrid strategies: pure water in open towers (with basin heaters or drain-downs), and glycol blends in closed or adiabatic cooling equipment.

| System Type | Freeze Risk | Common Issues | Best Protection Measures |

|---|---|---|---|

| Open-Circuit Tower | Lower (if basin is drained or heated). External pipework still vulnerable. | Burst external pipework, cracked basin if unheated. | Lagging & cladding, trace heating, basin heaters or drain-down during winter. |

| Closed-Circuit Tower | High — process water in coils freezes quickly without circulation or glycol. | Coil rupture (very costly to replace). | Continuous circulation, glycol dosing, insulation & trace heating, strict winterisation checks. |

| Adiabatic Cooler | Medium-High — spray lines and sumps freeze if unprotected. | Split spray headers, damaged valves/pumps. | Installation of FPU units, glycol dosing in circuits, insulation, trace heating. |

Environmental Factors in the UK

Not every site faces the same freeze risk.

- Scotland & North of England: Higher frost frequency, often requiring FPUs and glycol blends as standard.

- Midlands & South East: Fewer freezing days, but exposed sites (airfields, open industrial estates) still experience burst pipes if unprotected.

- Coastal Sites: Salt air can accelerate corrosion in insulation jackets, leaving pipework vulnerable over time.

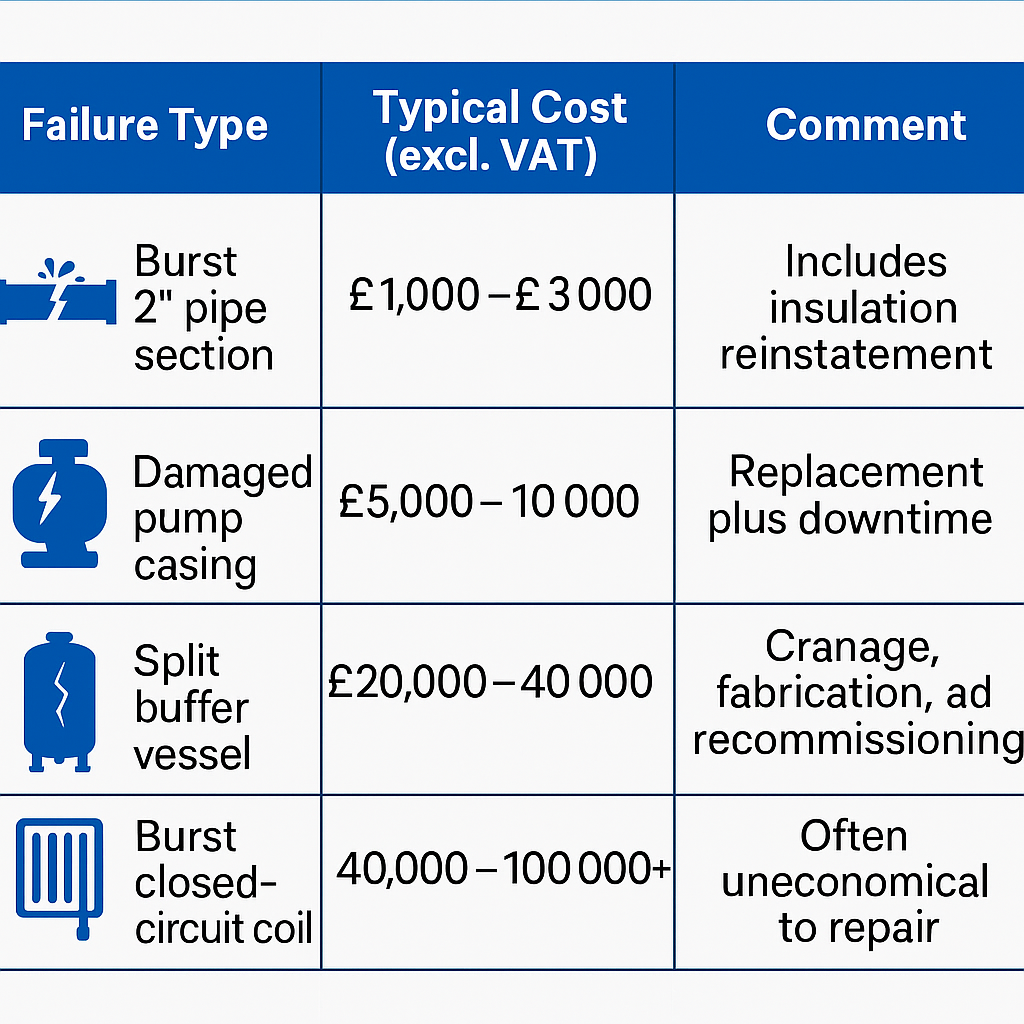

The Cost of Freezing vs Prevention

Compared to these figures, the cost of proactive measures lagging, trace heating, glycol dosing, or FPU installation, is minor – typically costing less than 10% of one major failure.

System-Wide Freeze Protection Measures

Effective protection requires whole-system thinking:

- Pipework: Insulate and trace-heat exposed runs; design drain-downs for seasonal lines.

- Pumps: Drain or maintain low-flow circulation during idle periods.

- Buffer Vessels: Fit immersion heaters or drain when off-line.

- Closed-Circuit Coils: Maintain flow or glycol protection; never leave stagnant.

- Adiabatic Units: Fit freeze-protection units (FPUs) for spray lines.

- Filtration: Insulate dosing pots and strainers; trace-heat or drain.

- Control Logic: Configure BMS to prevent pump shutdown when ambient falls below 2 °C.

For detailed engineering surveys, see Technical Services – Site Surveys.

Vistech’s Approach

Avoiding freeze damage is rarely about one size fit’s all fix – it’s about understanding how the entire cooling system behaves under frost conditions.

Our engineers provide winter readiness surveys covering pipework, vessels, coils, pumps, and FPUs. You’ll receive quantified risk findings and clear recommendations before the first freeze hits.

🔗 Book a Freeze-Protection Survey

🔗 Explore Our Technical Services

🔗 Learn About Lease vs CAPEX Options