Factors That Affect Cooling Tower Efficiency

When designing a new cooling tower installation or replacing an existing one, it’s important to consider several factors that can affect the efficiency of the cooling tower. These factors include water flow rate, temperature range, approach temperature, and design wet bulb temperature. Within limits for a given heat rejection, the most efficient tower selection will be obtained by opting for the widest temperature range and highest cold-water temperature, giving the greatest approach temperature.

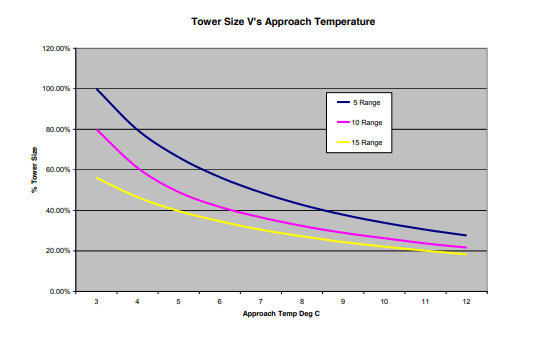

In addition, the graph below illustrates how the cooling tower size changes for a given heat rejection with increasing approach and range. As the approach temperature increases, the cooling tower size decreases. Moreover, increasing the temperature range also results in a reduced flow rate, which can lead to lower pump energy and smaller pipeline size.

If the cooling tower is a replacement unit, it’s essential to verify that the design parameters are still valid, as cooling requirements could have changed since the original installation.

Factors That Affect Cooling Tower Efficiency

When installing a new cooling tower or replacing an existing one, it’s crucial to consider several factors that can improve the performance and efficiency of the tower. Energy consumption can be reduced by using low-speed axial flow fans instead of centrifugal fans, which can cut energy consumption by 40 to 50%.

Corrosion is often the leading cause of cooling tower failure or the need for major overhaul. By selecting materials such as GRP or 316 stainless steel, not only is the risk of Legionella reduced, but so is the total life cycle cost. These materials are inherently corrosion-resistant, independent of water quality, which can more than double the life of the typical tower, from 10 to 15 years to 20 or even 30 years, without the added cost of maintenance that would be required with lesser materials.

Accessibility and Inspection

Adequate safe access, both inside and outside the cooling tower, is also crucial. New installations require careful consideration of how heat transfer packing and drift eliminators can be easily and safely removed or inspected, and how mechanical equipment such as fans, drive belts, and bearings can be serviced. Access platforms should be installed below the heat transfer packing to eliminate the risk of fatal falls from height inside the tower during cleaning or maintenance.

In conclusion, by considering these important factors, you can ensure that your new or replacement cooling tower installation performs efficiently and effectively for years to come.