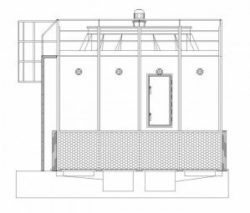

General Features

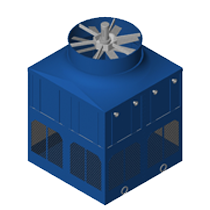

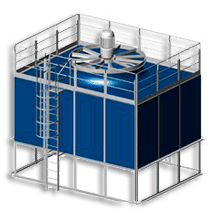

- Modular design

- Corrosion free

- Industrial applications

- Easy maintenance

- Big capacity (500 – 10.000 m3/h)

Configuration

Additional Equipment

- Sound Attenuator.

- Access ladder & Hand rail to the fan motor.

- Vibration Switch.

- Frequency converter

- Basin in FGRP

Working Principles

Cooling towers bring a cold and dry air mass in counter-flow to hot water that comes from an industrial or air conditioning process. Part of this water evaporates, cooling the rest. The necessary heat for this is approx.597 Kcal/liter. The cold water produced is returned into the process to re-initiate the cycle. The equipment with this evaporative refrigeration principle are very important for energy efficiency in industrial processes.

The difference between the required cold water temperature and the wet bulb temperature (called cooling limit distance), is significant to determine the size of the tower. The smaller the cooling distance is, the bigger the interchanging surface is needed. The limit distance must be of at least 3-4º C.

In open cooling towers there is a close contact water-air, which is bigger thanks to the fill packings, that provide a big surface of exchange, improving performance and evaporation. There are different kinds of fill packing for different water quality.