General Features

- FGRP Casing and stainless steel plate heat exchanger

- Direct driven fan motor (no pulleys and belts)

- Total corrosion resistance

- Easy cleaning

- Easy installation

Configuration

| Model | * Dissip. (kW) | Dry Weight (kg) | Service Weight (kg) | Pump Power (kW) | Fan Power (kW) | Length (mm) | Width (mm) | Height (mm) | Dim. Drawing | Plane DWG | Technical Features |

|---|---|---|---|---|---|---|---|---|---|---|---|

| EWK-I 144 | 185 | 635 | 945 | 4.0 | 2.2 | 2046 | 1559 | 2825 | Open | Download | [-] |

| EWK-I 225 | 260 | 813 | 1382 | 5.5 | 3.0 | 2319 | 1745 | 3100 | Open | Download | [-] |

| EWK-I 324 | 347 | 1221 | 1947 | 5.5 | 4.0 | 2638 | 1988 | 3425 | Open | Download | [-] |

| EWK-I 441 | 520 | 1656 | 2739 | 7.5 | 5.5 | 3002 | 2150 | 3459 | Open | Download | [-] |

| EWK-I 680 | 798 | 2529 | 5085 | 15.0 | 7.5 | 4132 | 2724 | 4550 | Open | Download | [-] |

| EWK-I 900 | 1040 | 2640 | 5701 | 15.0 | 11.0 | 5079 | 2724 | 4485 | Open | Download | [-] |

| EWK-I 1260 | 1433 | 5051 | 10191 | 2 x 15.0 | 15.0 | 4836 | 4332 | 4770 | Open | Download | [-] |

| EWK-I 1800 | 2080 | 5720 | 13810 | 2 x 15.0 | 15.0 | 5538 | 4836 | 4805 | Open | Download | [-] |

| * Heat rejection at the following conditions: Tin: 35,0 ºC, Tout: 30,0 ºC, Twb: 24,0 ºC | |||||||||||

Additional Equipment

- Sound Attenuator.

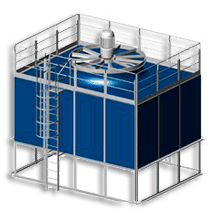

- Access ladder & Hand rail to the fan motor.

- Vibration Switch.

- Electric water control level in the Basin .

- Winter Pack (Thermostat & immersion heater)

- Variable speed drives, control cabinets.

- Water treatment systems (Dosing, bleed)

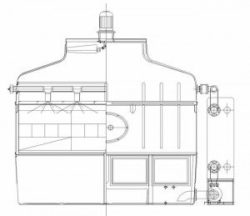

Working Principles

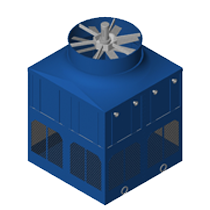

The fluid to be cooled (usually water) flows through the water passages of the stainless steel plate heat exchanger without coming into direct contact with the external air, preventing dirt or pollution from entering the primary water circuit. The heat is transmitted from the fluid through the wall of the heat exchanger plates to the cooling water from the tower, which is being continuously circulated through the heat exchanger.

The fan at the top of the tower draws air through the tower in counter-flow to the water, thereby evaporating a small amount of the re-circulating secondary circuit water. The evaporative process causes cooling of the remaining water and the heat is released to atmosphere,. The remaining water is re-circulated by the spray water pump from the basin to the spray nozzles. A small quantity of heat is transmitted by sensible heat transfer to the external air, in a similar manner to an air cooler.