General Features

- Broad Range: From 500 to 10.000 m3/h)

- Modular design in GRP

- Corrosion free

- Standard Fill materials in Polypropylene with anti-legionella treatment (SANIPACKING®)

- Industrial applications

- Easy maintenance

- German engineering

- Materials highly resistant to all aggressive conditions, as well as to extreme temperatures

- Pre-assembled at the factory

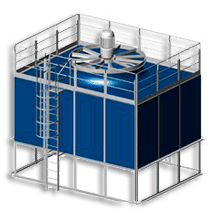

- Three different options:

- A) WITH complete integrated sump and inlet louvers

- B) WITHOUT integrated sump but WITH inlet louvers

- C) WITHOUT integrated sump and WITHOUT inlet louvers

Configuration

| Model | *Dissipation kw | Empty weight kg | Service Weight (kg) | Fan Power (kW) | Length (mm) | Width (mm) | Height (mm) | Dim. Drawing Concrete Raft | Plan Dim. Polyester Raft |

|---|---|---|---|---|---|---|---|---|---|

| EWK 2100 | 3372,6 | 5100 | 19100 | 22 | 4740 | 4610 | 6750 | Open | Download |

| EWK 3100 | 5117,1 | 6800 | 24800 | 30 | 7040 | 4610 | 7095 | Open | Download |

| EWK 4500 | 7267.5 | 10100 | 36400 | 37 | 7040 | 6900 | 7255 | Open | Download |

| EWK 4200 | 6745,2 | 10300 | 34700 | 2×22 | 4740 | 9240 | 7050 | Open | Download |

| EWK 6200 | 10234,2 | 13800 | 49800 | 2×30 | 7040 | 9240 | 7395 | Open | Download |

| EWK 9000 | 10234,2 | 20400 | 72900 | 2×37 | 7040 | 13850 | 7555 | Open | Download |

| NO BASIN (B) |

|||||||||

| EWK 2100 | 3372,6 | 4200 | 5900 | 22 | 4740 | 4610 | 6150 | Open | Download |

| EWK 3100 | 5117,1 | 5600 | 8100 | 30 | 7040 | 4610 | 6655 | Open | Download |

| EWK 4500 | 7267.5 | 8300 | 12100 | 37 | 7040 | 6915 | 6495 | Open | Download |

| EWK 4200 | 6745,2 | 8500 | 11900 | 2×22 | 4740 | 9240 | 6450 | Open | Download |

| EWK 6200 | 10234,2 | 11400 | 16400 | 2×30 | 7040 | 9240 | 6955 | Open | Open |

| EWK 9000 | 14535,0 | 16800 | 24300 | 2×37 | 7040 | 13850 | 6795 | Open | Open |

| NO BASIN / NO LOUVERS (C) |

|||||||||

| EWK 2100 | 3372,6 | 3300 | 5000 | 22 | 4740 | 4610 | 4175 | Open | Open |

| EWK 3100 | 5117,1 | 4400 | 6900 | 30 | 7040 | 4610 | 4520 | Open | Open |

| EWK 4500 | 7267.5 | 6500 | 10300 | 37 | 7040 | 6915 | 4680 | Open | Open |

| EWK 4200 | 6745,2 | 6700 | 10100 | 2×22 | 4740 | 9240 | 41752 | Open | Open |

| EWK 6200 | 10234,2 | 9000 | 14000 | 2×30 | 7040 | 9240 | 4520 | Open | Open |

| EWK 9000 | 14535,0 | 13200 | 20700 | 2×37 | 7040 | 13850 | 4680 | Open | Open |

Additional Equipment

- PRFV with SANIPACKING® treatment casing

- Access ladder & Hand rail to the fan motor

- Access door in Polypropylene

- Vibration switch for ventilation equipment

- Electric motor frequency converters

- PTC sensor for the motor

- Exhaust silencer

- Low noise fan

- Sensors for the level of water in the basin

- Winter pack (Thermostat & Immersion heater) to protect from low temperatures

- Attenuators of noise from the drops in the basin

- SMART Cooling Tower

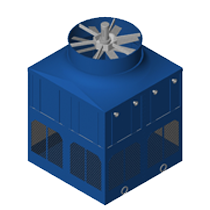

Working Principles

Cooling towers bring a cold and dry air mass in counter-flow to hot water that comes from an industrial or air conditioning process. Part of this water evaporates, cooling the rest. The necessary heat for this is approx. 597 Kcal/litre. The cold water produced is then returned into the process to re-initiate the cycle.

The difference between the required cold-water temperature and the wet bulb temperature (cooling limit distance), is significant to determine the size of the tower. The smaller the cooling distance is, the bigger the interchanging surface is needed. The cooling limit distance must be at least 3-4º C. In open cooling towers there is a close contact water-air, which is bigger thanks to the fill packing, providing a large heat exchange surface, improving performance and evaporation.