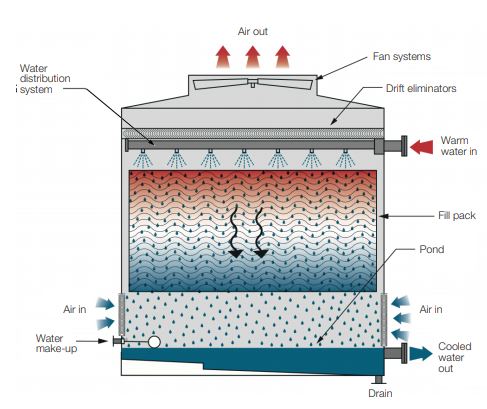

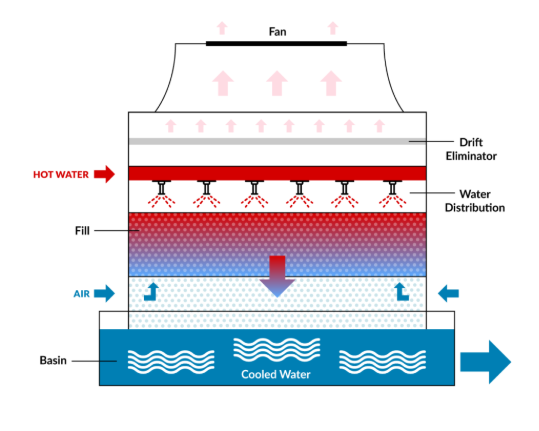

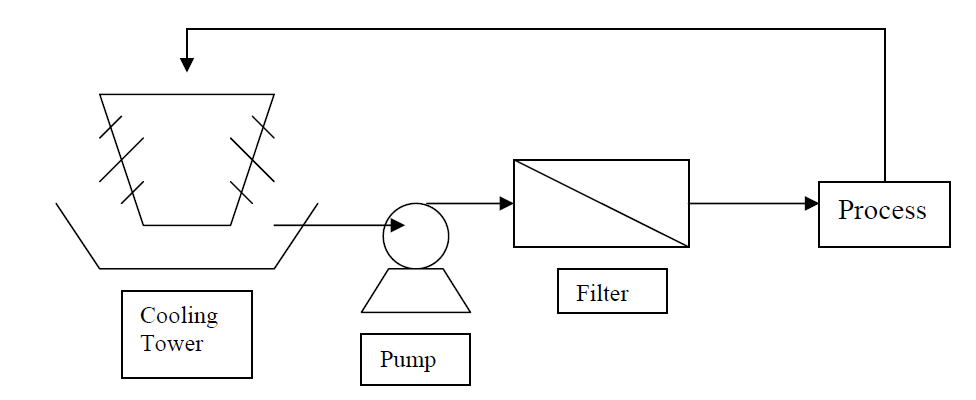

Cooling water is used in numerous industrial and commercial applications. The method by which the water is cooled can make a serious impact on the operating costs and operation of a system. The object of this paper is to consider the primary solutions, their advantages / disadvantages limitations and their impact on both energy consumption and operating costs.

There are many combinations of cooling equipment and variations to their design that it is not practical to compare all types of cooling tower with all types of adiabatic and dry cooler etc. The comparisons within this paper are therefore based on the common standard selections in each instance. It is important to point out that, the particular requirements of an individual project should always be considered. However, this paper provides a good starting point for many applications.